Application Fields:

Architecture&Furniture, Automobile Industries and Household Appliances, etc.

Heating Mode:

Combination of radiation and assisstant convection heating.

Glass Can Be Tempered:

On-line Low-E Glass, Ultra Clear Glass, Screen Printed Glass, Pattern Glass, Tinted Glass, Clear Glass, etc. Product Introduction

LandGlass’ research and development history in the field of variable curvature glass tempering started several years ago when the straightness of the straight edge of bent glass products’ was yet a technical challenge. Since then, LandGlass had tried three different kinds of bending technologies. Finally in 2011, after the combination of intelligent servo control systems and innovative flexible bending mechanism, LandGlass made a breakthrough in the development of Variable Curvature Glass Tempering Furnaces. The newly developed bending technology not only provided a better final product but it also improved reliability and extended the life of the equipment. In 2012 LandGlass showed the industry its “J Shape” tempered glass products. In 2013 LandGlass introduced the “U Shape”

Glass Tempering Furnace.

AirStreamTM Radiation Heating plays a supportive role during the process. Compressed air is injected into the heating furnace to aid the heating process of the top surface of the glass, which ensures heating uniformity for on-line Low-E glass, and other glass types.

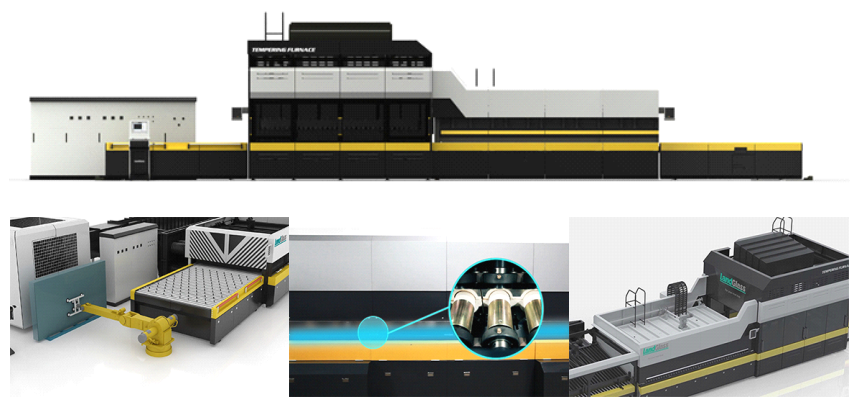

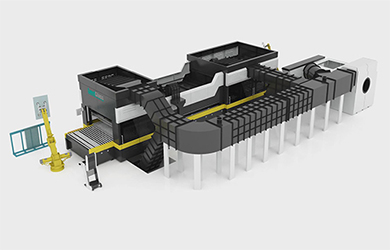

LD-D AirStreamTM Variable Curvature Glass Tempering Furnaces are mainly used to bend and temper variable curvature glass.

They are demanded to produce the glass for commercial refrigerators, food showcases, and high-class buses. The intelligent servo control system and flexible arching mechanism are applied to the furnace, which can process various kinds of high-quality variable curvature glasses through the innovative process and furnace layout.

Technical Features

1. The innovative arc forming technique and the flexible bending mechanism ensure the flexibility and fast adoption of the curvature. The high precision bending mechanism ensures the accuracy and stability of arc forming.

2. There is no movement in the bending mechanism during the bending process, which ensures the glass accuracy and repeatability, reducing daily maintenance.

3. Glass that can be tempered includes: on-line Low-E glass, extra ultra clear glass, screen printed glass, pattern glass, tinted glass, clear glass, etc.

Technical Parameters

| LD-D Series Variable Curvature Glass Tempering Furnaces | ||||||

| Model | Max. Loading Dimensions(mm) | Min. Loading Dimensions(mm) | Thicknes s(mm) | Min. Radius(mm) Heating Power | Productivity (loads/h) | Installed Capacity(KVA) |

| LD-D1209/2 | 1200xARC900 | 300xARC300 | 4-8 | 250 240 | 25-28 500 | |

| LD-D1512 /2 | 1500xARC1200 | 300xARC300 | 4-8 | 250 320 | 25-28 630 |

1. The Min. Radius is calculated on min. thickness white glass. Actual radius is subject to different glass thickness, shapes and types;

2. The dimensions in parentheses are optional according to customers’ special requirements;

3. Productivity is calculated on min. thickness white glass. Actual productivity is subject to different glass thickness, types and dimensions;

4. Other models are not listed as the space here is limited.

Customer Case

| Company | Nanxin Glass Limited Company |

| Location | Jiangsu, China |

| Company Profile | Nanxin Glass Limited Company is a large-sized enterprise with a plant area of 12,000 ㎡ and over 150 employees. The company boasts several advanced production lines and corollary equipments, mainly producing flat and bent tempered glass, insulating glass as well as special glass and art glass. Its products are widely used in architecture, furniture, household appliances etc. Featuring advanced equipments, excellent quality and perfect service, the company has won high popularity and become a brilliant glass processing enterprise in the Yangtze River Delta. |

| Furnace Type | LD-D Series Variable Curvature Glass Tempering Furnace |

| Main Products | Tempered glass products, heavy machinery glass, refrigerator glass, train accessory glass, bathroom glass and so on |