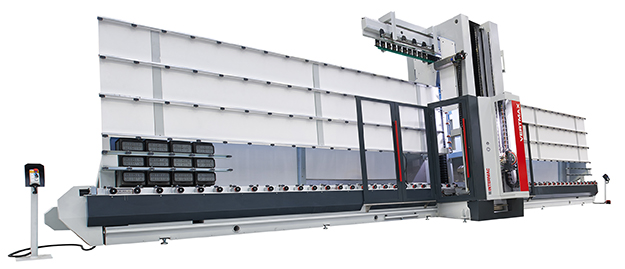

V Series are born from the careful analysis of the ever growing need of flexibility from the producers of structural glass, doors and also from the examination of the technological solutions today available in the sector of vertical machines. With V Series some innovations already tested and developed for other technologies are introduced in this type of machines, in order to achieve a work tool that is characterized by high flexibility and that allows to carry all the machining operations needed to produce structural glasses and doors with a single machining cycle, without needing to carry the grinding and squaring of the glass sheet on another machine, thus granting a high automation level and a good quality result. The machine control is carried through a commercial Windows PC that grants ample connection and ease of use.

Glass handling system During the processing, glass sheets are moved through a motorized belt through a system of motorized belts and pressure rollers to grant optimum grip on the piece.

Tool change (opt.) The machine can be equipped with double revolver tool change where is possible to load the tools in complete safety. The tool changes are placed at distance from water and scrap that could cause damage and bad functioning.

PC based IWNC numerical control V Series are equipped with the IWNC numerical control integrated into a personal computer with a Windows interface. The advantages of this solution are evident and introduce a new standard in the design of this type of machine. The use of a PC with Windows XP operating system is extremely simple and intuitive for the operator and provides full connectivity with commercially available network systems and optical/magnetic supports.

The PC is supplied complete with CD-ROM drive, modem and network card, 15” colour monitor and Windows XP operating system.