Application Fields:

Automobile Roof panel

Heating Mode:

radiation or convection heating

Glass Can Be Tempered:

on-line and off-line Low-e (E=0.02) glass, ultra-clear glass, screen-printed glass, pattern glass, tinted glass, clear glass etc.

Product Introduction

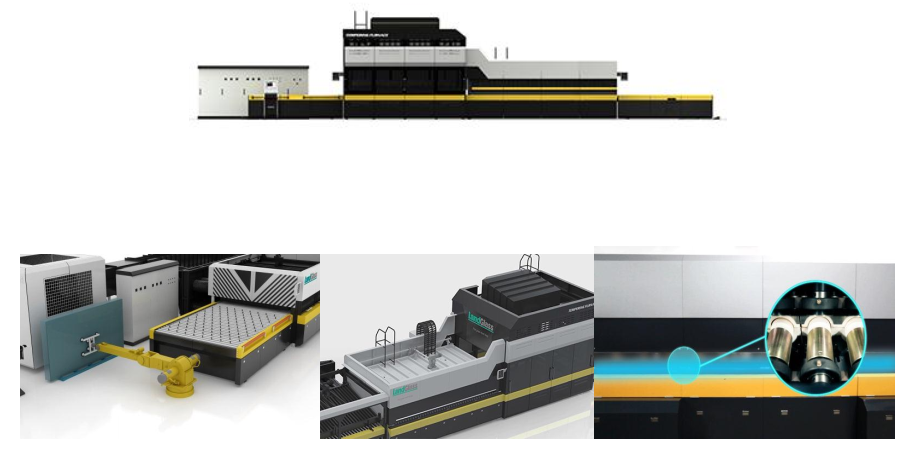

Adopting the latest vacuum suction molding technology, ideal for mass production of roof panel.

Optional smart control solutions are available for comprehensive, flexible, and powerful equipment management.

High quality

and lean production of tempered glass can be achieved based on state-of-the-art technologies.

Technical Features

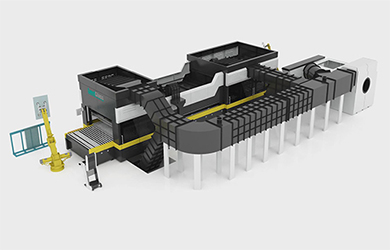

Servo driving – fully adopting servo driving system in bending section for high location accuracy;

Vacuum suction – creating close contact between mold and glass for precision shaping with vacuum suction;

Custom chiller – customized chiller in conformity with the shape of the glass to ensure the uniformity of tempering stress;

Air cushioned unloading – avoiding damage to glass, improving glass surface quality;

Dual-mold trolley – less processing time for higher output;

Lowered roller table – allowing steady running of bending roller.

Technical Parameters

| E1610/3 V | |

| Max. Dimension | ARC1600 * ARC1000 |

| Min. Dimension | ARC400 * ARC500 |

| Glass Thickness | 3.2-6 |

| Max. Height of Curvature | 120 |

| Capacity | 60-65 |

| Installed Capacity | 1500kVA |

| Company Name | BSG Auto Glass Co., Ltd. |

| Company Location | Dafeng City, Jiangsu Province |

| Introduction | Specialized in automobile glass manufacturing, BSG Auto Glass Co., Ltd is one of the major industrial projects in Yancheng City. The company is equipped with several state-of-the-art production lines for upscale automobile glass, primarily developing, making, and selling high performance, sound and thermal insulating glasses for luxury vehicles. |

| Equipment Type | LD-E1610 |

| Main products | Various types of laminated windshield glasses, side window glasses for luxury cars, buses, trucks, and recreational vehicles. |