Genius 37 RS-A is a series of machines designed based on the standards of CNC cutting machines for cutting straight and cubic format glass. One of the revolutionary technology innovations on this series is that it is controlled by a Windows interface computer, providing users with convenient, connected and easy-to-use proven proven policies for Worldwide customers of Intermac. The Genius 37 RS-A is a versatile machine with modular programmable programs that fully meet the needs of small and medium-sized processors.

Genius 37 RS-A cutter head

Genius 37 RS – A is equipped with a high-tech cutter combined with an automatic cutting control system. This device has the effect of controlling the stolen pressure of the glass cutter from the beginning to the end of the cutting process, automatically adjusting the cutting pressure based on the shape of the cut line. The computer with the speed control function of the spindles, together with the high-quality mechanical and electrical equipment, optimizes the cutting time, providing flexibility and continuity for the operation of the machine.

Genius 37 RS – A operating system

Genius 37 RS-A brings a whole new technology in the field of glass cutting machine which is IWNC digital control integrated with personal computer running Windows interface. With a Windows-based computer, the Genius 37 RS-A provides high technology, ease of use, intuitiveness and provides connectivity to the worldwide network. Computers are equipped with CD-ROM, modem and network cards, 17 ” color screen and Windows XP. Computer modems and remote service software allow remote machine diagnostics, as well as software upgrades or changes, without the need to stand directly. At the same time, this technology also allows the webcam to be connected to the computer, saving time sending pictures or data to the warranty and after-sales department of Intermac. 3-dimensional design machine, C-axis completely independent rotation unlimited for fast cutting curve (conventional machines will not have independent C-axis design so when the curved cut will run slowly and the cutting head will be strokes down the glass, not automatically rotate according to cutting requirements).

The machine has the function of grinding brush low.e in the form of brushes

The machine has a bone lift system to load and unload glasses.

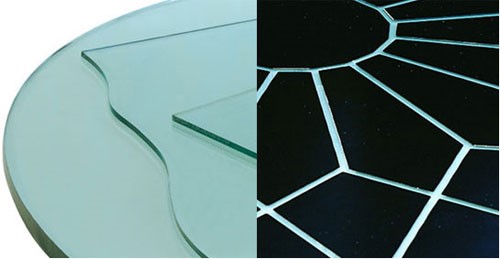

The machine can cut plotter glued on glass so that the processor can cut any sophisticated pattern, then peel off the negative part and sandblast or process with chemicals to form perfect glass art works. .

The machine has a copy function that helps the cutter copy the pattern of any product and then reload the cutting style so that the finished product cutter is 100% true to the sample product ordered by the customer.

The machine has a positioning at point 0 and automatic positioning with Lazer, so that it can place the glass sheet anywhere on the cutting table to be able to accurately shape the cutting and help the 2-layer glass cutter to be accurate when cutting face 1 move and flip section 4.

Includes full Iedit optimization software package, sticker creation software (with tools available for glass and logo design by glass outsourcer, customer name or customer code, order nature, barcode or QR code, software to import data from Exel file or Text file format).

Machine made in Italy