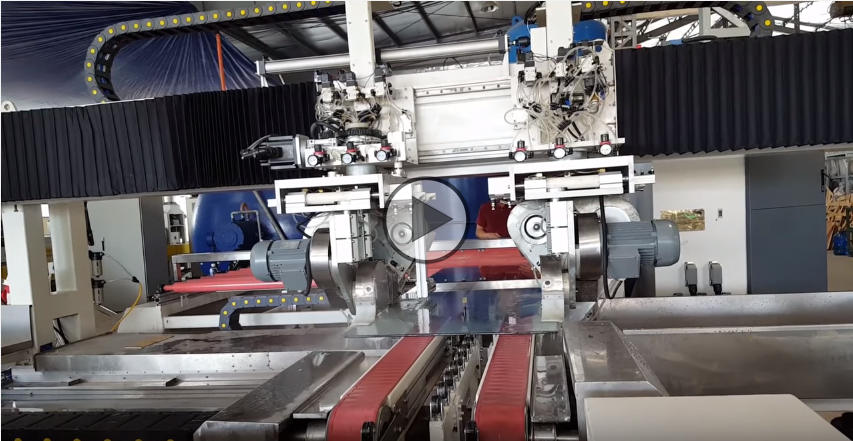

PHU SON Corporation HN inspected the entire system before commissioning the CHAOYANG high-tech safety laminated glass production line at the RICCO GLASS factory.

CHAOYANG with the superior technology and quality of equipment lines, the quality of laminated glass products always meet the highest standards and meet the most rigorous technical requirements for the high-rise glass walls. .

The difference of CHAOYANG laminated safety glass production line:

* Real equipment line “quality” and really beautiful on every detail even the smallest

* Modern overall design, high technology, intelligent control software

* The washing machine is designed with Bentteler technology – Italy super quality on all parts, controlled completely automatically via PLC and liquid crystal display, automatically stops fan loading when there is no glass entering the drying chamber saves energy and cuts the noise.

* The draw frame is designed with super smart and “quality” on every detail of components. The conveyor motion design with 3 compartments is independently controlled by 3 motors and 3 inverters to help maximize the production capacity. 4-position vertical and intelligent positioning structure incorporating glass-moving robot movement with servo motor & YASKAWA driver, sliding rail guide and gear movement, fully automatic control. Through PLC and liquid crystal display, it is possible to create paired glasses with perfect uniformity of all 4 sides. Multi-bowl design with fine-tuned sensors and springs and a soft rubber inhaler helps to assemble low.e covered or soft but not brittle glass panels like normal equipment. Design of automatic PVB film slitter with 3-reel independent remote control.

* Air bubble heat press machine with 4-lot ballast is designed to operate completely independently through 4 motors and 4 speed-adjustable gearboxes by inverter, the moving roller system is also adjustable. The speed by another independent inverter helps to completely synchronize with the whole chain system. Controlled by PLC and liquid crystal display. Generate hot heat by infrared with radiant heat 1 preheating chamber and 3 main heat convection technology thermal convection technology by circulating fan system to ensure the production of laminated low.e laminated glass and tempered laminated glass perfect, fast and uniform heat penetration, low surface glass heat … help speed up production and ensure quality standards of all types of goods.

* High pressure chamber is designed to withstand 15MPA pressure with large forced draft convection fan to ensure the shipment completes the right technical design for the chemical components of PVB film, always in uniform, no bubbles air, the film layer is always flexible, tough and durable with time in all weather conditions. Controlled by PLC through the liquid crystal display of all steps of the manufacturing processes, from the temperature rise steps, pressure boost steps, immersion steps, convection fans, air supply, air discharge, water pump Fully automatic cooling.

* Each stage has a control system design through PLC, liquid crystal display and separate electrical cabinet is completely independent control and central control of the whole chain system.

* Glass is loaded continuously but never collides with each other and operates intelligently at all stages to optimize production speed.

* Electric cabinet system is designed and built super professionally and meets European CE standard

* Smooth and super smooth running line, stable, durable

* Industrial scale production 24/24 with very high output

* Finished products always meet 100% of standard I.

With perfect competence, experience and qualifications, PHU SON Corporation HN and HCM engineers are always 100% proactive in installation, technology transfer and after-sales service 24/24 without the presence. any of the expert engineers from the manufacturer over the years. This helps ensure that the installation progress and after-sales quality are done 24/7 professionally and effectively in any circumstance. All bring great benefits and value to customers, manufacturers and suppliers.