PHU SON Corporation installed the HISNEG automatic lying flat-bed automatic glass bottom and edge polishing industrial machine – 2023 at SOMVANG GLASS factory – a loyal customer in Laos.

The machine is controlled by PLC + liquid crystal display

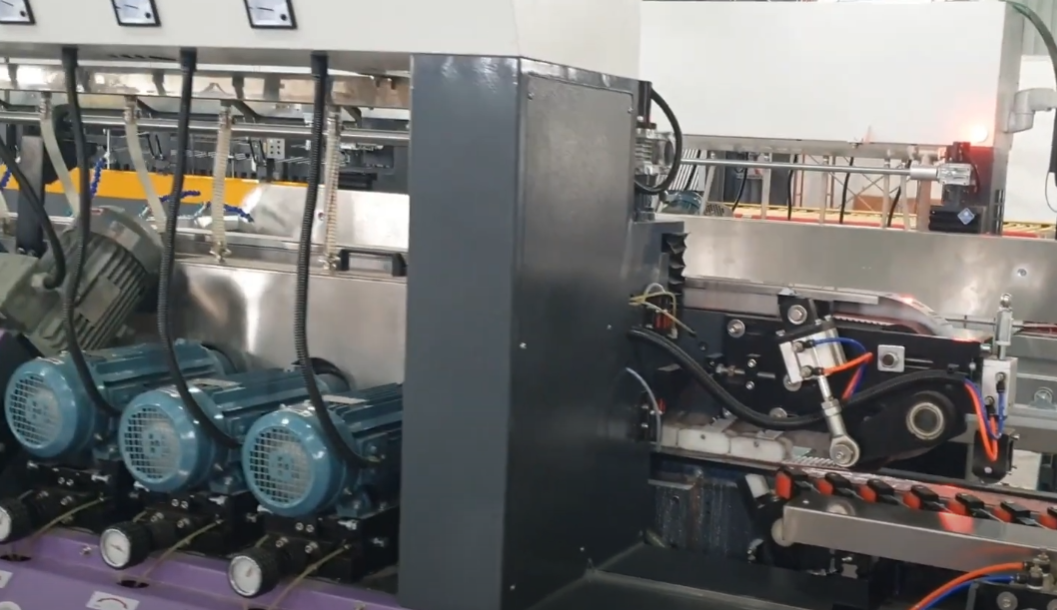

20 ABB . ball and grinding head motors

Maximum glass plate grinding size: 5000mm

Barcode gun kit integrated with intelligent control software to ensure sequential receipt of work orders in sequence with multiple orders at the same time to automatically adjust operating data without entering work order data export

The movement of 2 pairs of conveyors by 2 servo motors + 2 drivers helps to ensure absolute accuracy in synchronicity and working speed, which is convenient for connecting other automatic line-operated systems connected with machine (size and thickness measuring machine, washing machine, loading machine, automatic unloading machine…) according to new generation intelligent technology

The central support bridge is always automatically positioned in the middle when changing the width of the glass to ensure that the glass is always flat without any human intervention.

The machine is designed with a conveyor clamp on a specialized heavy-duty industrial saw blade that operates at a fast speed, so the water will rub off the surface of the glass and the machine is equipped with a pressurized air knife for preliminary cleaning. the surface of the glass plate as soon as the glass comes out of the machine

Horizontal movement by 1 servo motor + 1 driver is extremely fast and accurate to shorten the waiting time when changing the width of the glass.

Double-groove spiral shaft for precise operation and long-term durability

Electrical connection system and all electronic components according to European standards – CE.

The machine already has the tools available for future investment needs to connect into a high-tech smart line including an automatic table for measuring dimensions and thickness (machine 1 and machine 2 receive data and align full automatic fast speed).

***** The differences of the completely new generation machine – NEW DESIGN, NEW CONSTRUCTION, NEW TECHNOLOGY, NEW SOFTWARE, NEW FEATURES – SMARTER, FASTER, EFFICIENT:

* The main body base frame structure is designed with thicker and heat treated steel and is up to 1.8m wide, the fixed body and the movable body are designed on a unified standard block placed directly on The chassis body helps the machine operate completely smooth, stable, and not deformed.

* The base structure of the fixed side base body and the movable side base body is stronger and more stable

* Precisely designed guide bar and torsion shaft, more durable and stronger

* The gearbox on both sides of the machine is designed seamlessly from the engine to the gearbox to the transmission belt to be stronger, smoother and more accurate (the old design uses a sand shaft to connect the transmission between the gearbox and the fragile transmission belt). and weak motion force causes non-synchronicity ratio between 2 pairs of conveyors)

* Lower conveyor support body is made of #304 hardened stainless steel to make it stronger and more durable (old material is hard plastic)

* The machine has a structure of 6 bottom grinding heads divided 3 + 3, in which 2 rough + fine diamond grinding heads and 1 fine grinding wheel in the group of 3 pre-grinding heads. With the design of 3 front heads (No. 1 ~ No. 3) rough grinding + fine and smooth bottom of the glass edge, the same design of 2 heads (No. 4 ~ No. 5) finely and finely grinded on both sides of the glass edge, so if only rough grinding is can push the speed to increase significantly when the glass runs through the grinding head position 5.

* Lower edge grinding head: Using the most advanced design for the lower 45 degree edge grinding system of the glass plate by 2-step operating structure with motor on top (connected to the grinding head rack via speaker wire) , very convenient for alignment, maintenance and smooth operation, the polishing line quality is better (the old design was a direct grinding head motor and was located below).

* The machine is designed with a drainage groove so that water does not overflow on the area of the grinding head slides (the old design did not have a drainage groove, so water can overflow into the slides of the grinding head racks)

* The upper pair of conveyor cleaning brushes is designed to be open for easy viewing, adjustment and replacement (the old form is the brush placed in the box)

* The groove of the grinding heads uses a straight slide system to help the ball head motor slide smoothly and operate more stably (the old type uses fish gill structure).

* The use of a more advanced water supply system structure reduces the risk of glass powder deposition and the stronger water pressure keeps the grinding heads free of the risk of water shortage to increase the level of perfection for each wheel operation grinding

* The structure of the glass inlet locator is designed in the form of fan-shaped steel sheets

* Drivers, inverters and transformers are installed separately into an independent electrical cabinet to prevent interference with other electronic components.

* All the slides of each grinding head rack are designed with a full lubricating oil supply system to help all grinding heads operate smoothly.

* The machine is equipped with a system to increase the tension of the upper conveyor belt by phiton and is automatically controlled, changing the conveyor belt only needs 1 operation on the screen without having to remove the bolts like traditional

* The machine is equipped with an ultrasonic sensor at the inlet to increase controllability throughout the process