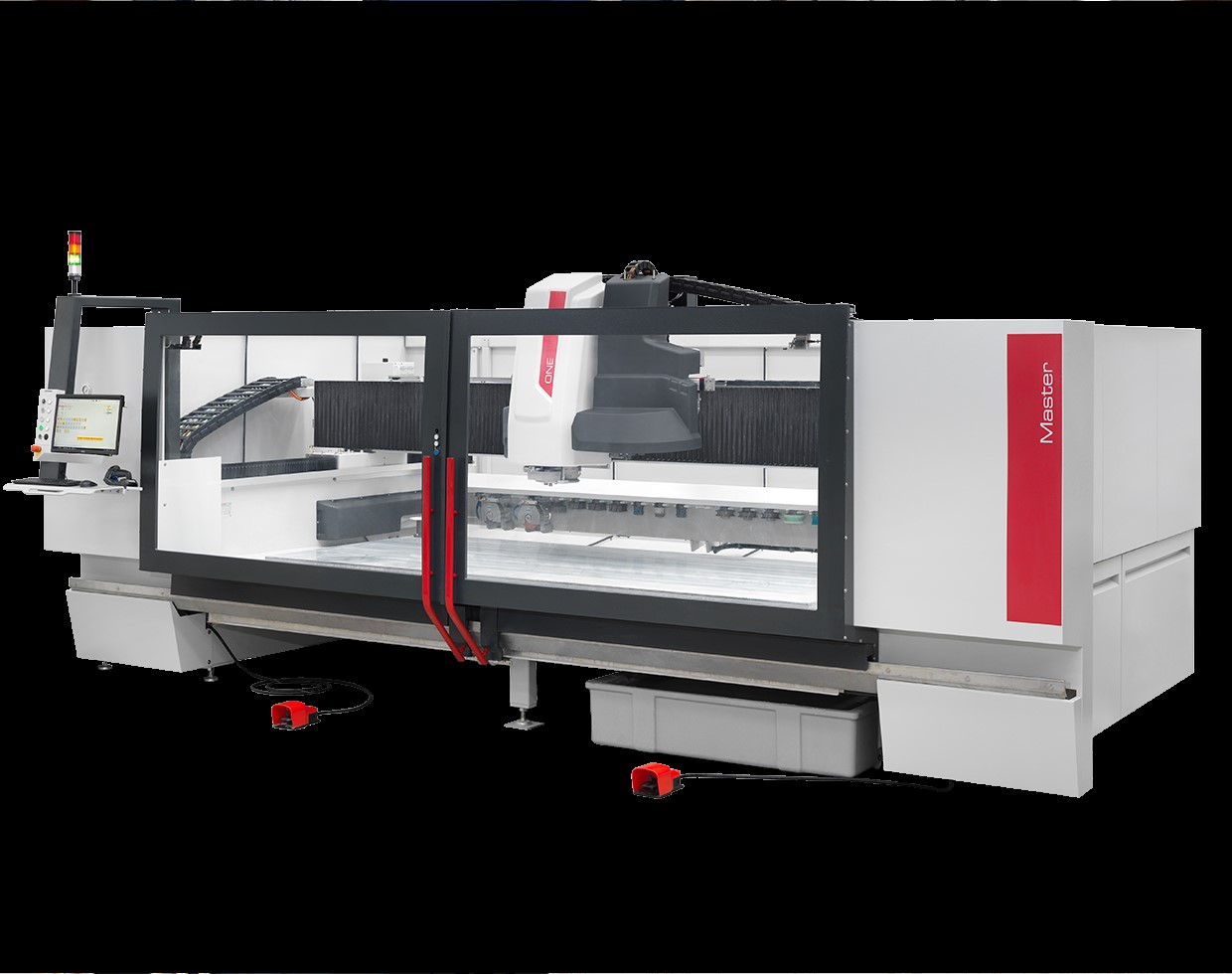

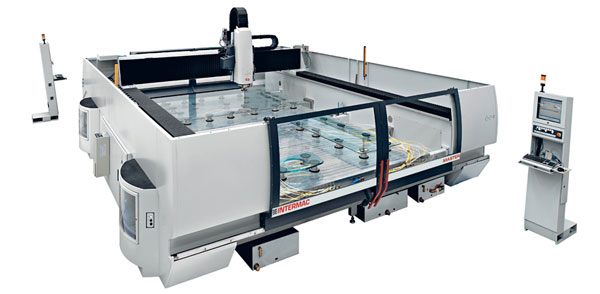

The PC based numerical control work centre, Master 23 is Intermac’s new proposal dedicated to the glass processing. The careful analysis of the commercial and technical requirements filtered by Intermac experience, have brought to the conception of an easy operating machine, where the numerical control is completely integrated into the PC structure with Windows XP, operating system that allows automatic machine management and high configurability. Thanks to its high technology and flexibility, Master 23 can be adapted to the specific productive and economic requirements of the client and offers the possibility to select between different configurations. It satisfies the requirements of big enterprises and little craftsmen through the optimum management whether of the complex and long duration workings, whether of the short workings dedicated to the production of large series, reaching high quality results with a reduced investment.

PC based IWNC numerical control (Intermac Windows Numerical Control)

PC based IWNC numerical control (Intermac Windows Numerical Control)

Master 23 is equipped with the IWNC numerical control integrated into a personal computer with a Windows interface. The advantages of this solution are evident and introduce a new standard in the design of this type of machine. The use of a PC with Windows XP operating system is extremely simple and intuitive for the operator and provides full connectivity with commercially available network systems and optical/magnetic supports. The PC is supplied complete with CD-ROM drive, modem and network card, 15” colour monitor and Windows XP operating system. The PC modem and teleservice software enables remote diagnostics and software. It’s possible to connect a webcam to the PC, to save and transmit in real time to the service department, instant images of some details of the machine.

Operator interface

The new operator interface in Windows XP is simple and user friendly. It allows to begin the processing schedule in order to grant the positioning optimisation of the pieces to be processed. The operator interface also allows to quickly and simply enter the various programs which are in the control unit, such as the origin management, the tools management and the daily production statistics which can be useful to calculate the machine’s productivity. The operator interface is completely integrated with the drawing and programmino softwares such as ICad, ICam, IDoors and with the various application softwares that can be installed on the PC on board of the machine. Extremely important is the possibilità to perform the processing, programming and the personalization of tools parameters and machine’s data while the work centre is working, totally avoiding the passive time still present in the machines of our competitors.