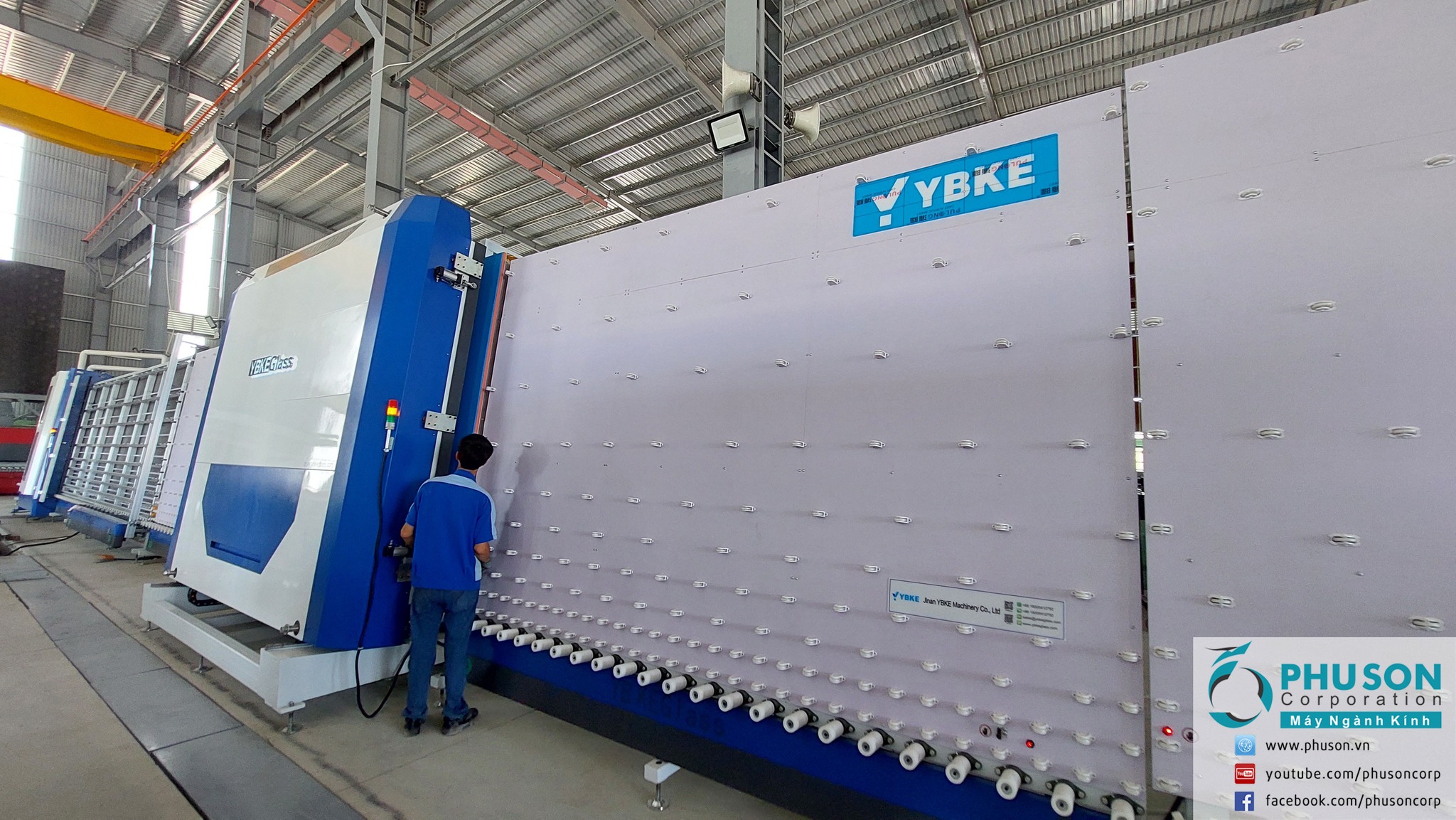

PHU SON Corporation HCM has completed the installation and transfer of YBKE automatic glass insulating production line with on-line argon gas filling technology at NAM CHAU GLASS factory. This is the latest generation of automatic production line for insulating and soundproof double-glazed glass to save energy. The production line is designed and manufactured with outstanding features:

* High technology

* Many superior features

* Modern industrial design

* Really suitable investment budget

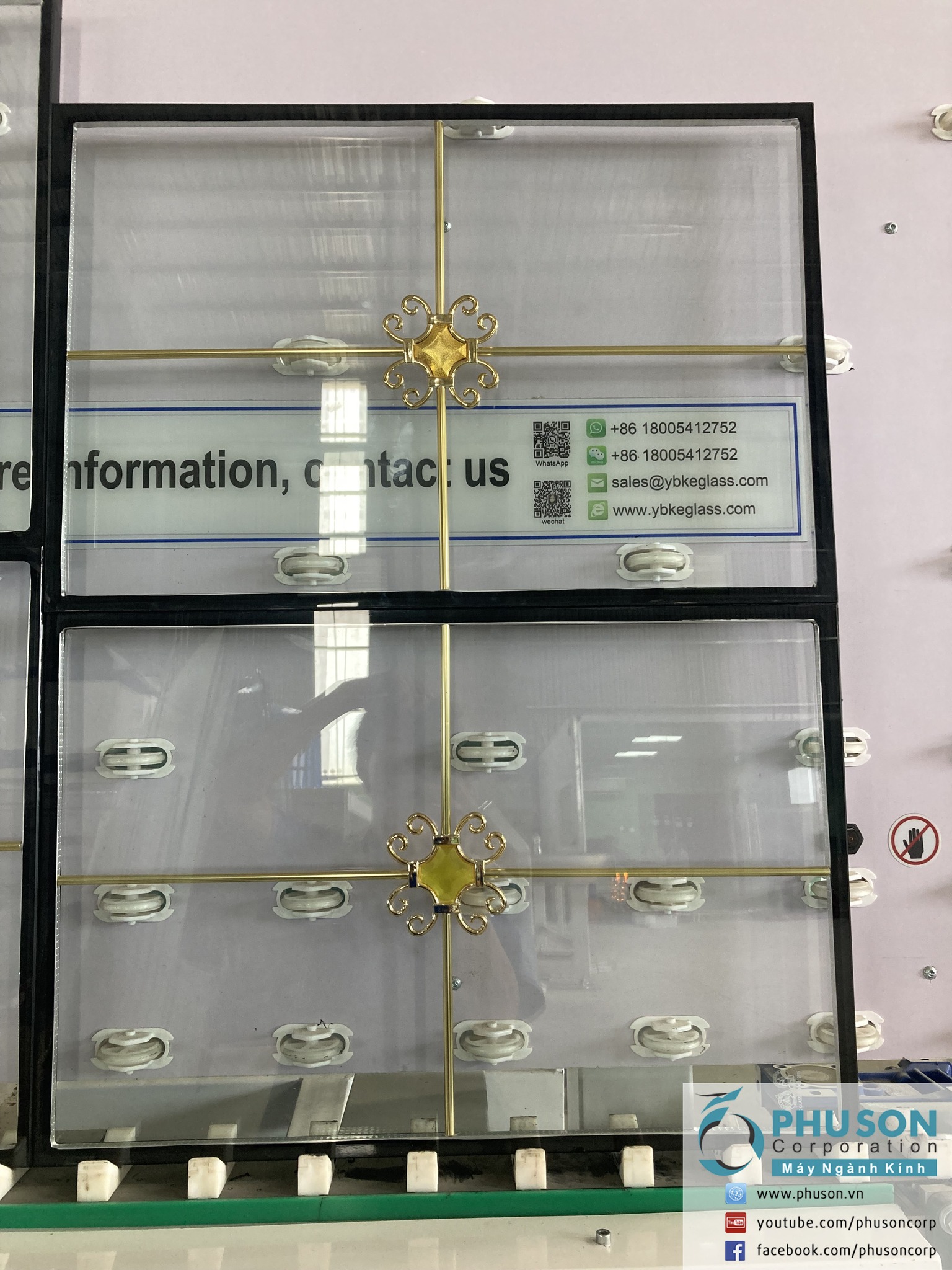

* Production of double-glazed glass with low.e glass and soft-coated solar control

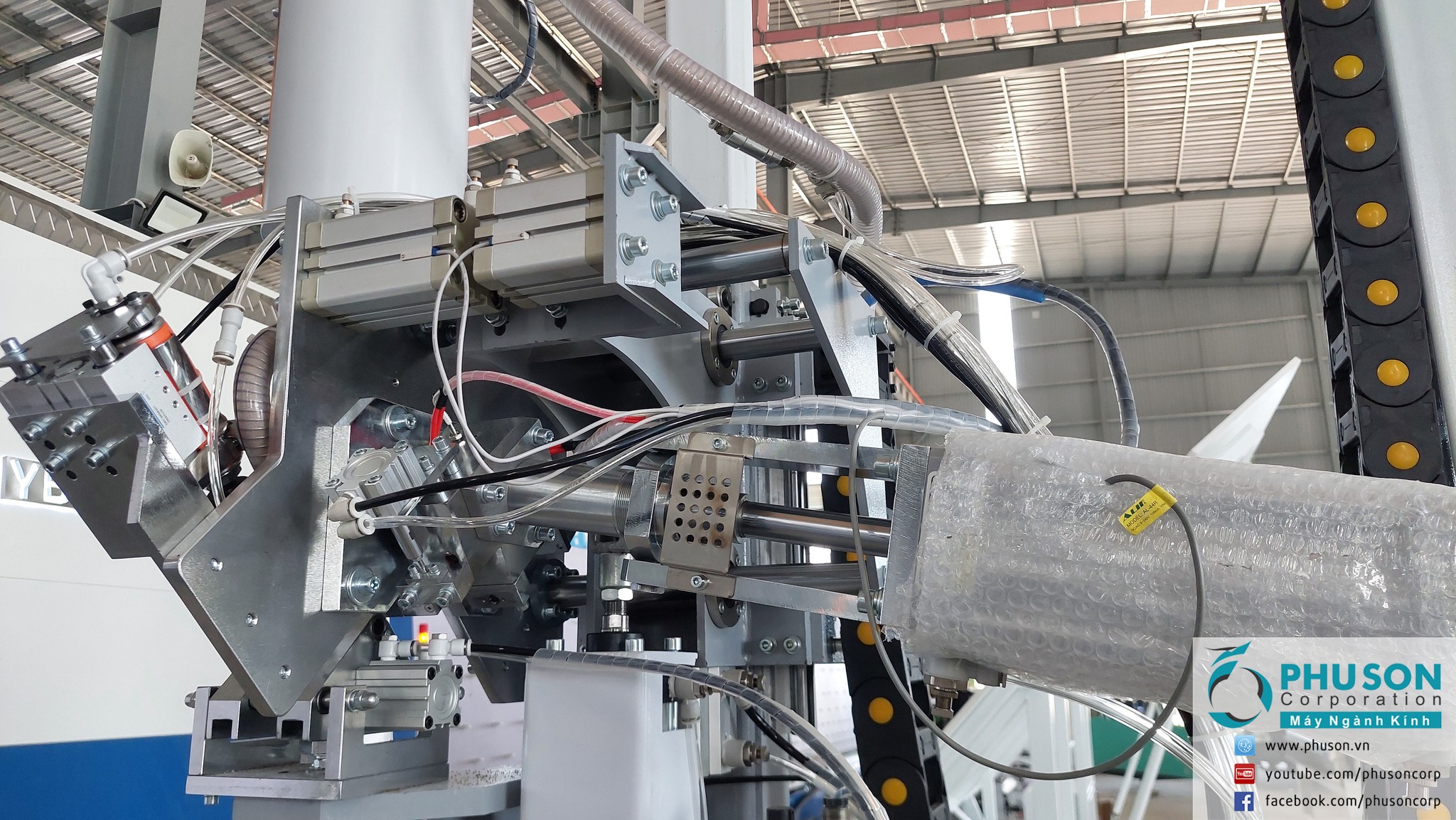

* Flat pressing technology to create double-glazed glass boxes operated by servo motors with 4 guiding spiral shafts for absolute precision

* Fully automatic argon gas filling function on-line with smart features displaying gas filling ratio in real time and operated by servo motors that automatically control the foam stopper to run along the correct length of each glass box, helping to accurately fill the amount of gas for each size and width of each different glass box, helping to absolutely save argon gas.

* Automatic 3-layer glass box pressing function (2 vacuum compartments) helps to double the sound insulation and heat insulation, saving energy.

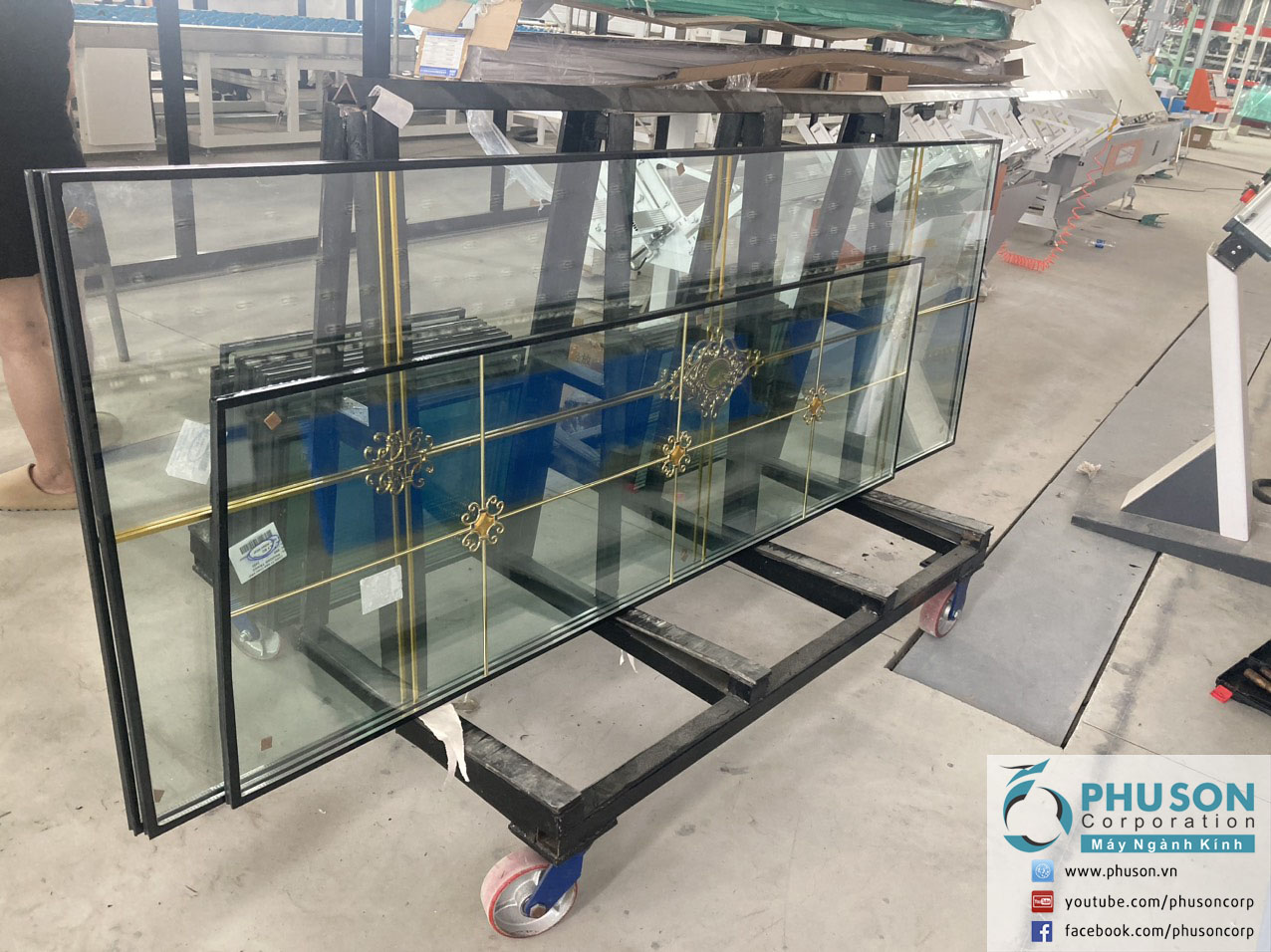

* The produced double-glazed glass products are of perfect quality, specialized for high-rise glass facades that require extremely strict technical conditions to ensure durability and safety for decades, covering buildings that are directly exposed to harsh natural weather conditions such as sun, rain, heat, cold, wind, and storms.

The production line includes the main line and auxiliary equipment:

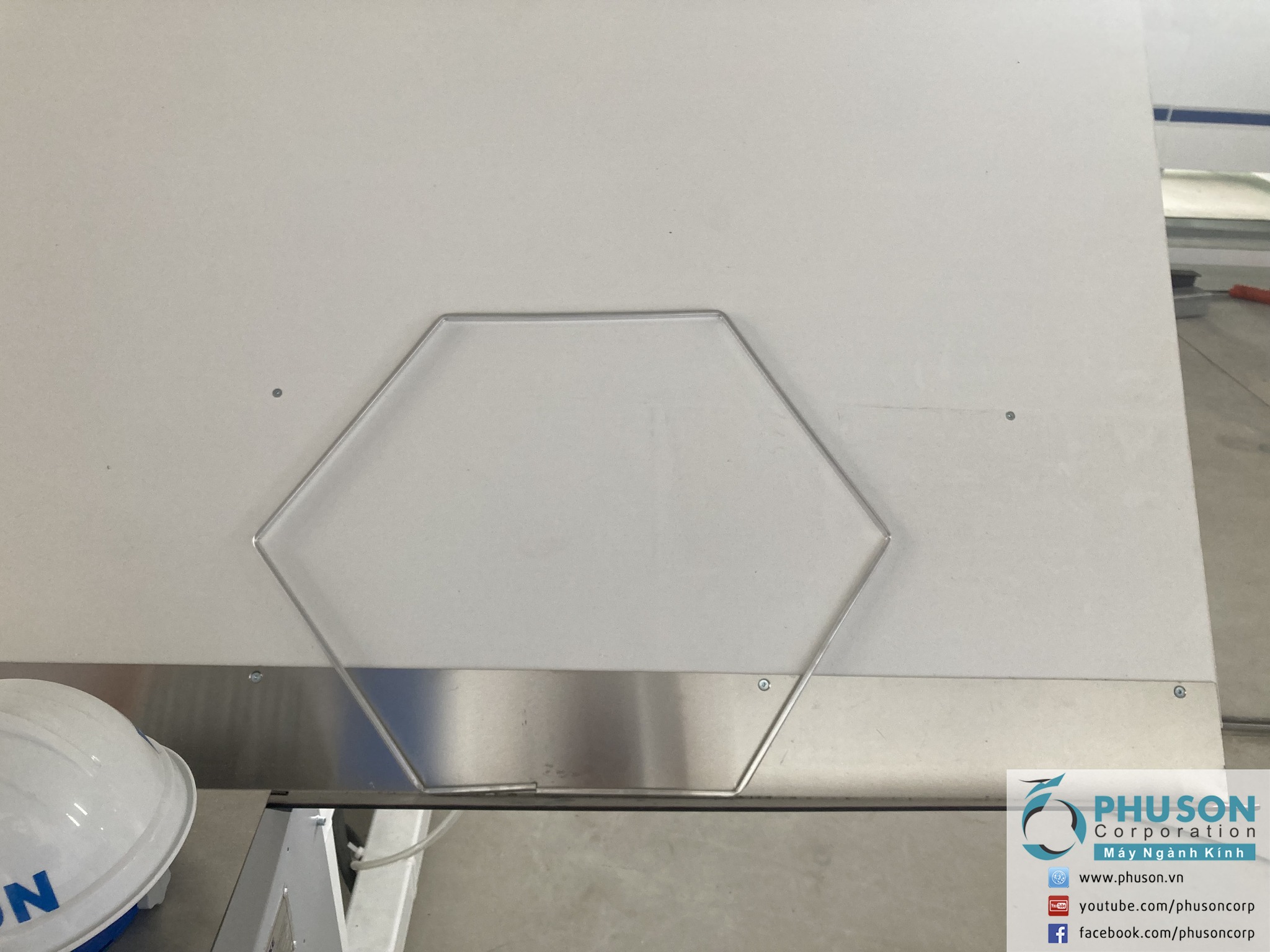

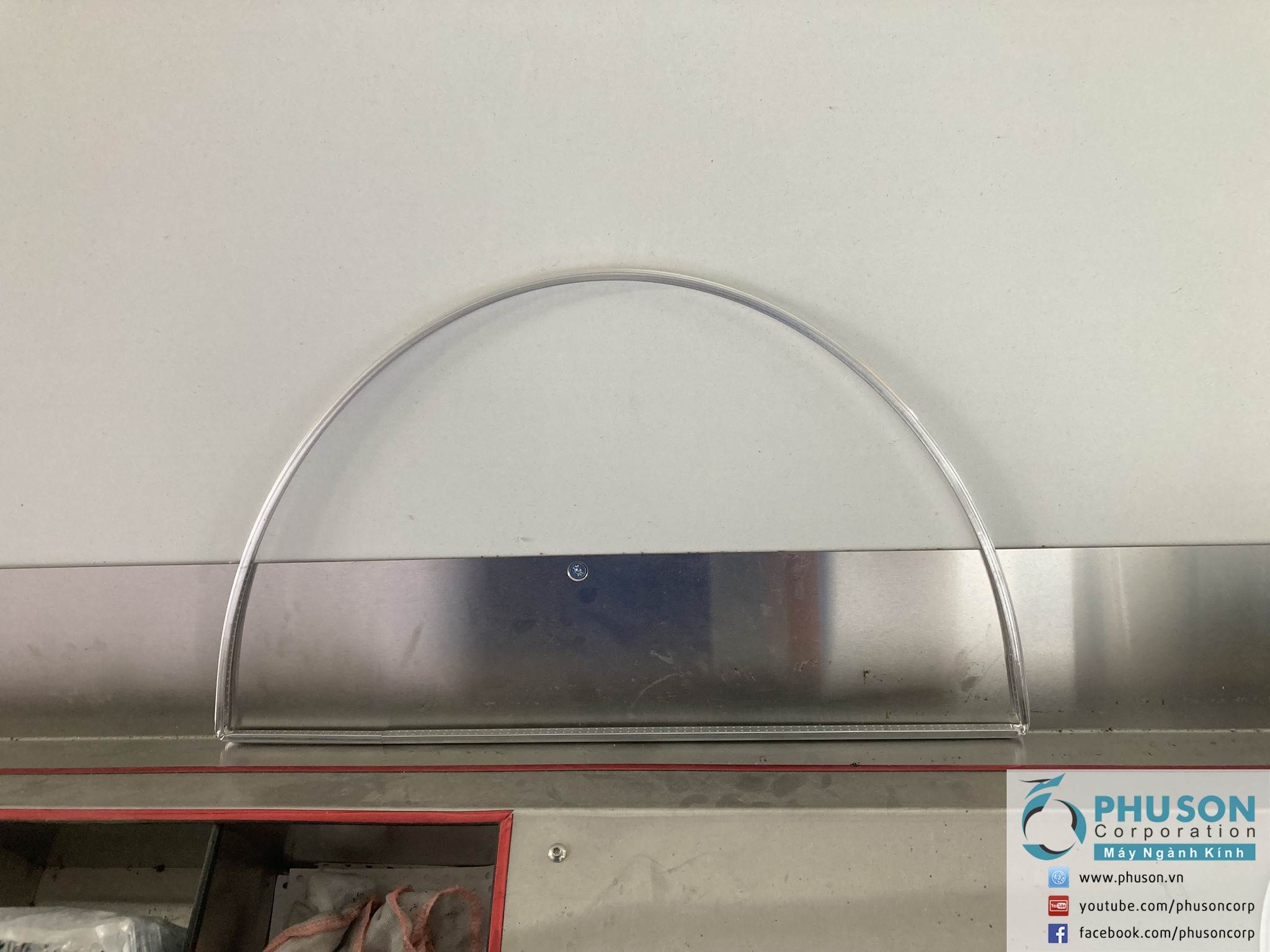

Automatic multi-shape aluminum spacer bending machine with label printing function

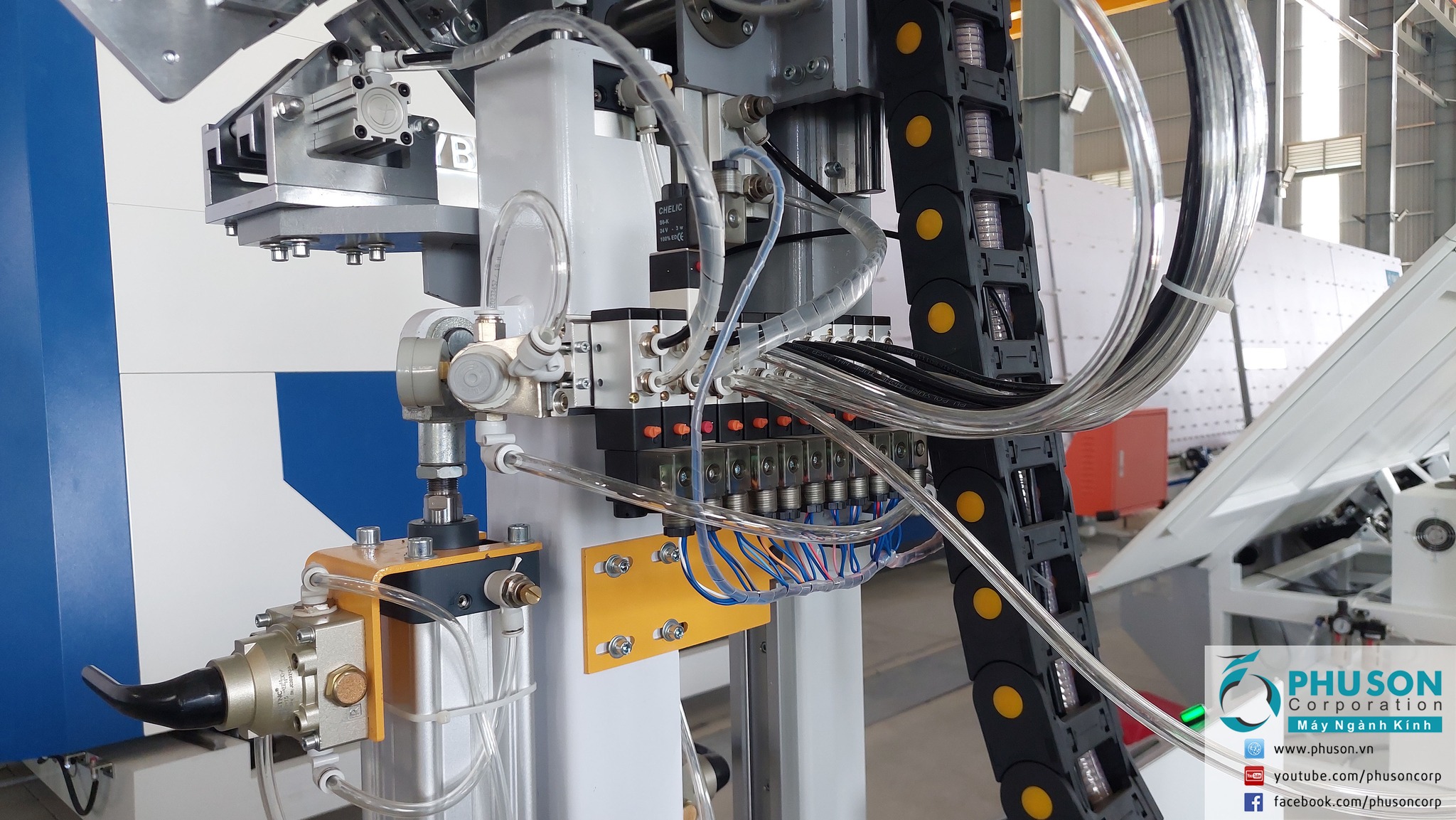

Butyl extruder

Automatic desiccant filling machine

Two-component sealing robot for multi-shape glass boxes and fully automatic 2-compartment glass boxes.