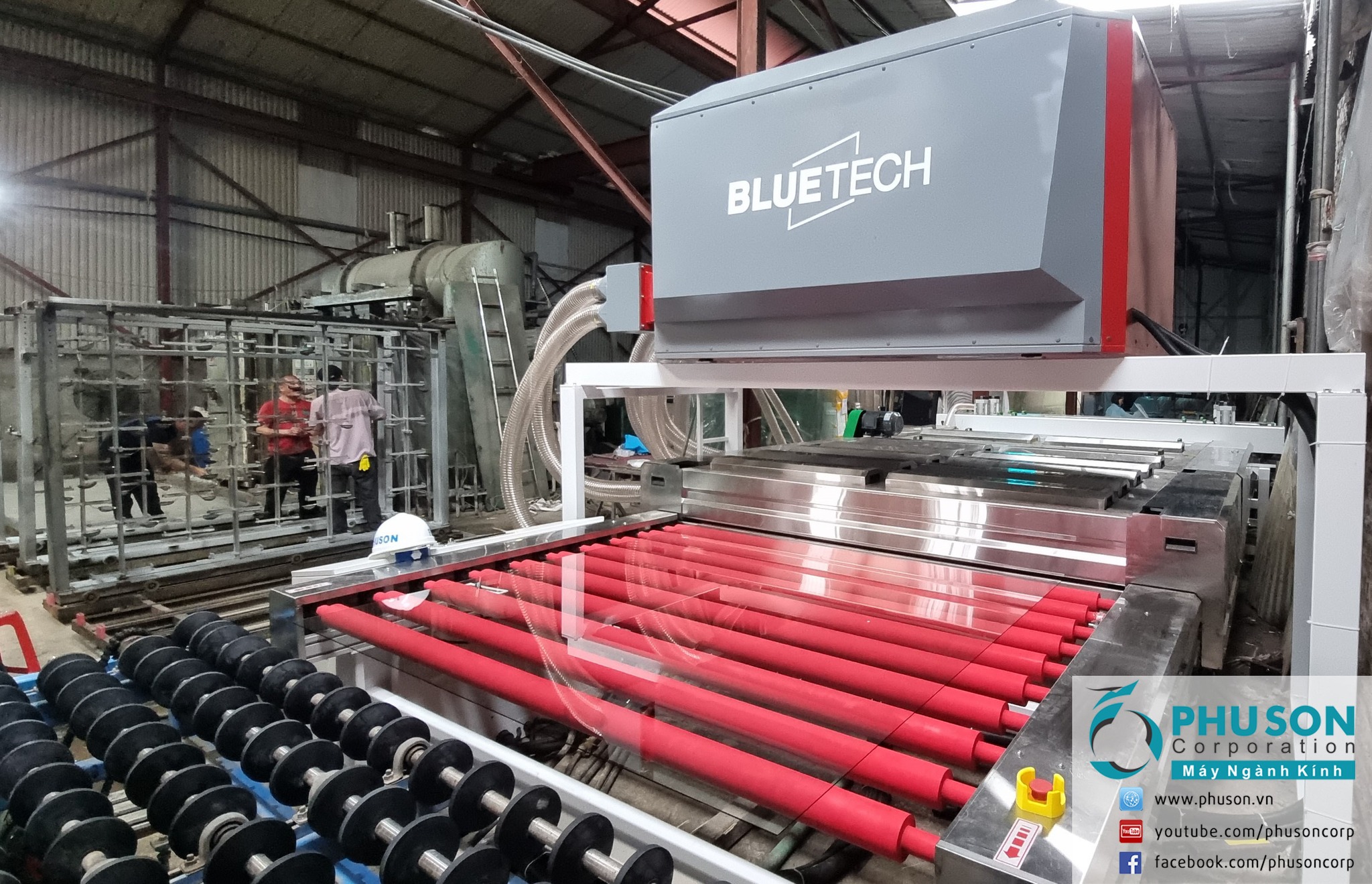

PHU SON Corporation has completed the installation and transfer of BLUETECH glass washing machine for the production of mirrors, reflective glass and low-e glass coated with super fast speed at LUYEN LUONG Mirror factory (DUC LINH GLASS) with absolute customer satisfaction when the washing speed is many times faster than the old washing machine and the quality of raw materials meets perfect standards after washing and drying.

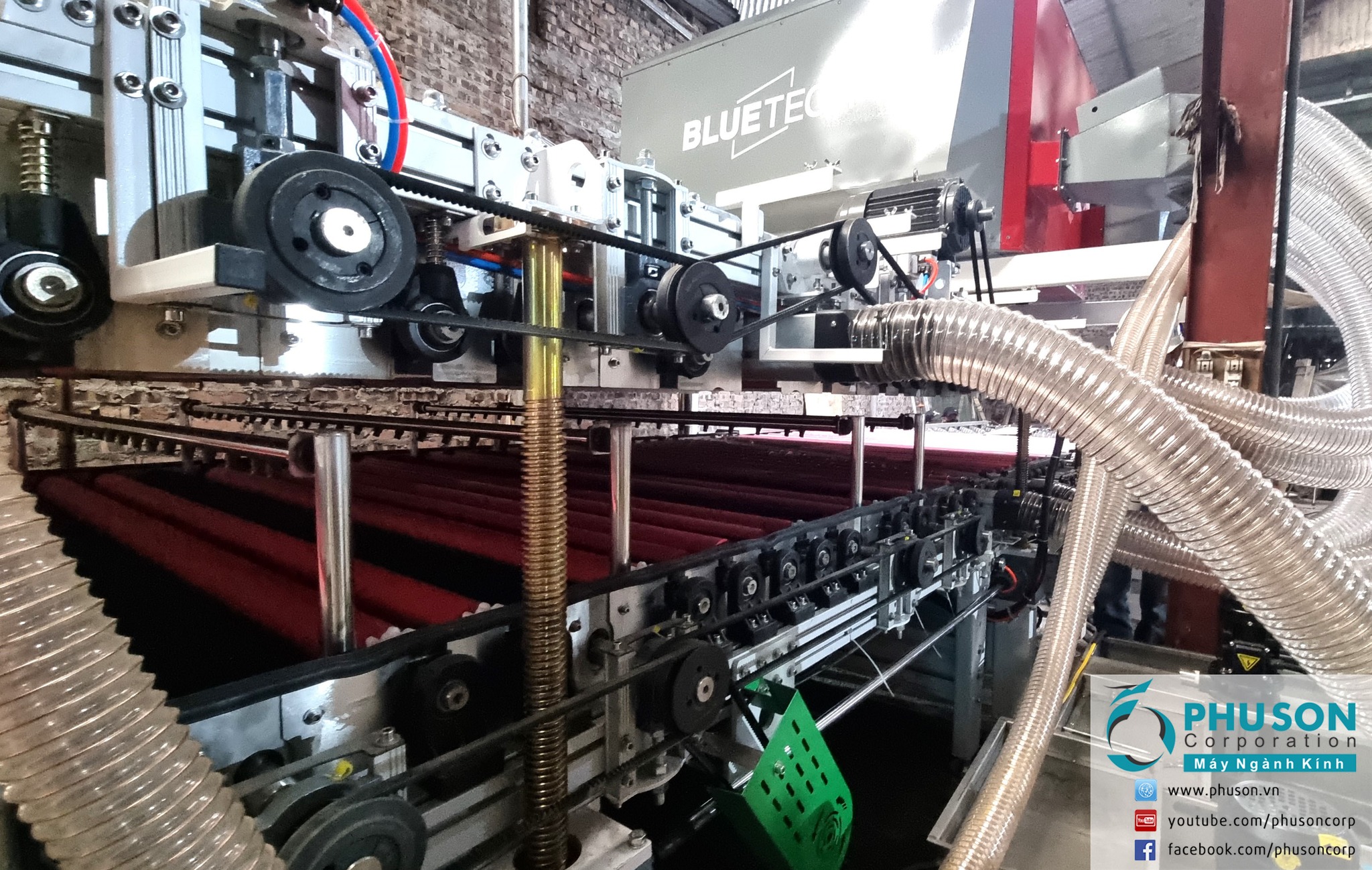

The machine is specially designed with the following details:

* Benteler technology washing machine – Italy, super fast washing, super clean and super dry

* Fully automatic operation, controlled via liquid crystal screen and PLC

* Design of 2 high-pressure fans to dry after washing

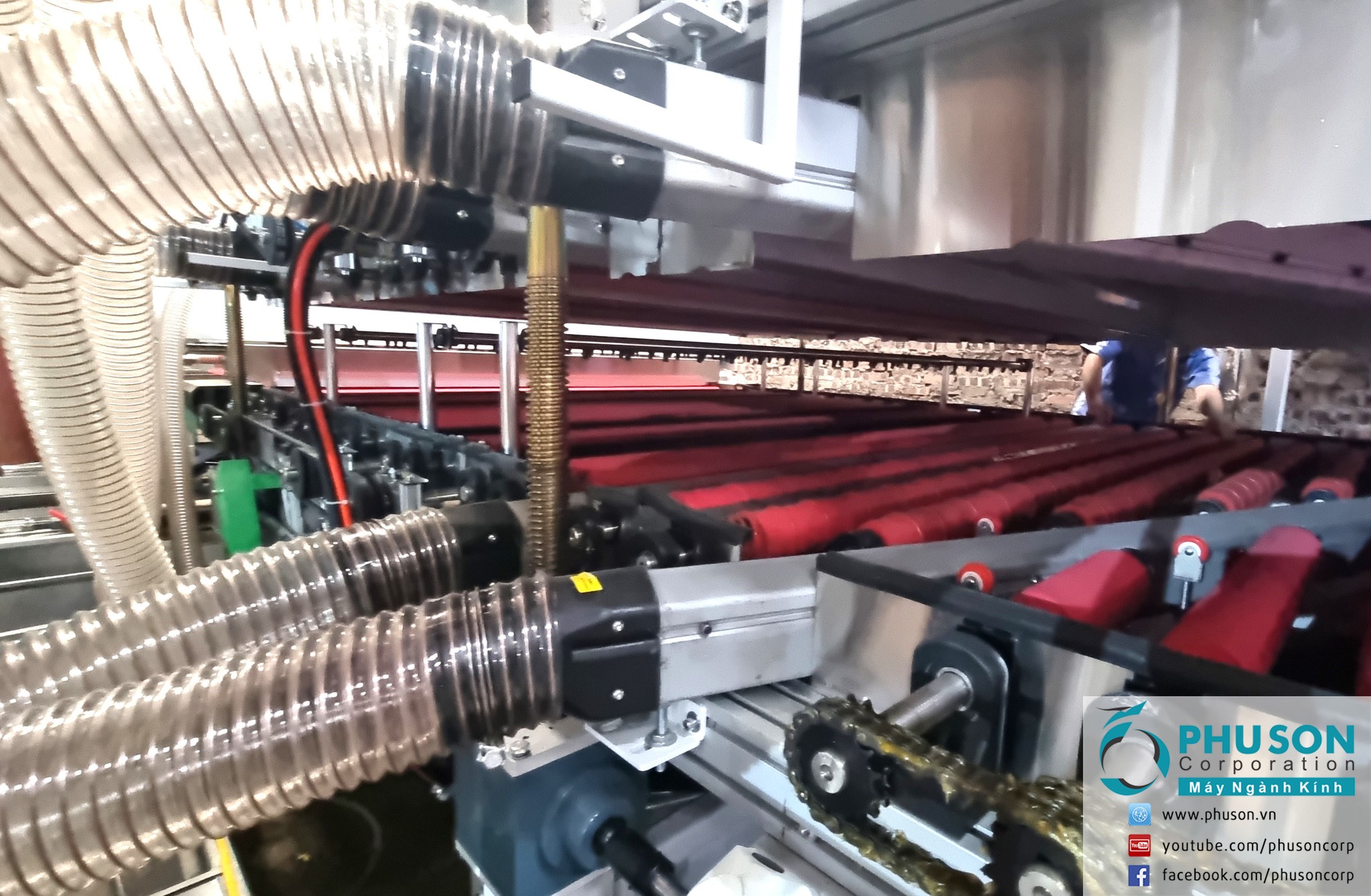

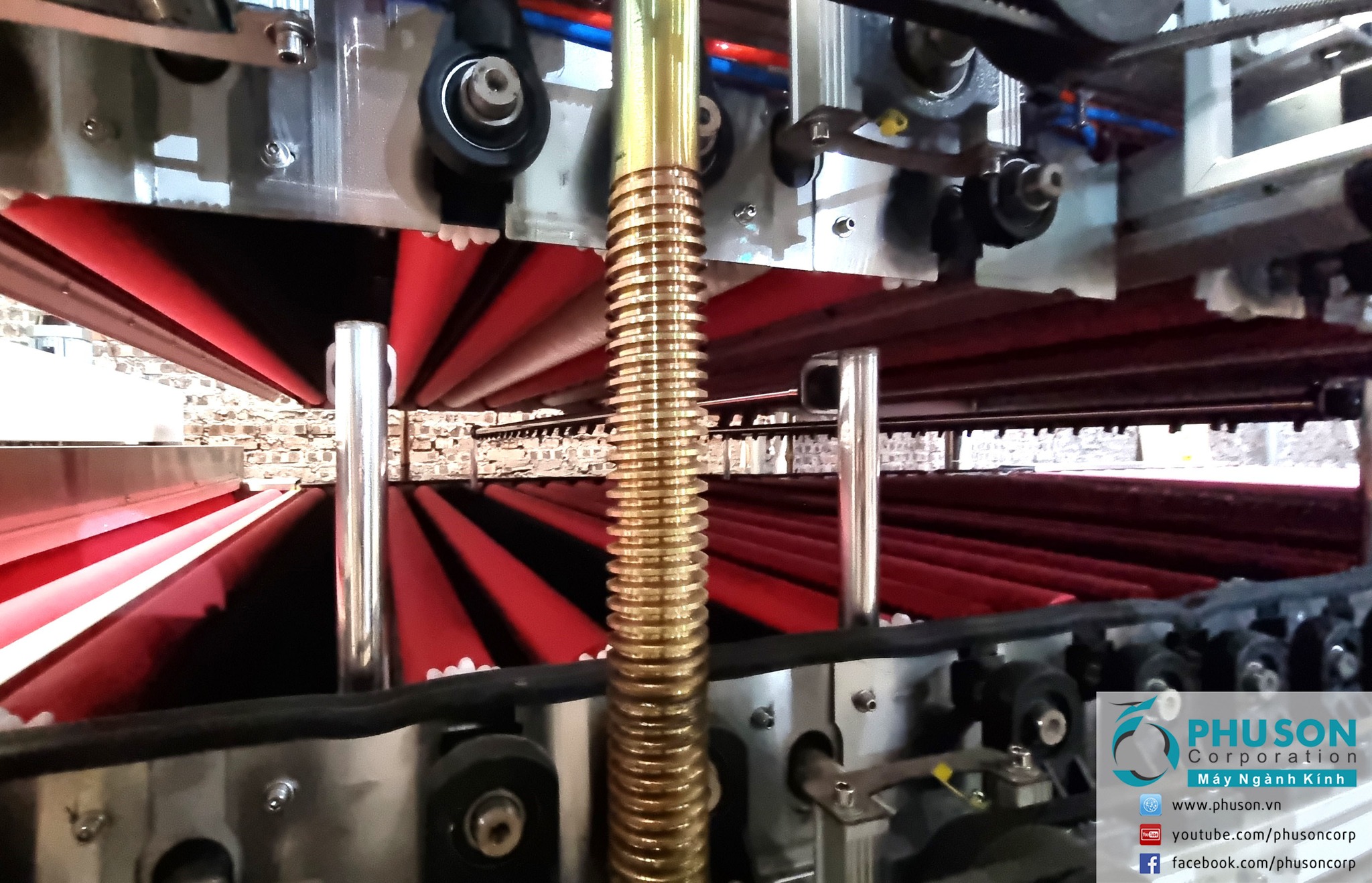

* With a structure of 8 roll-shaped washing brushes and 2 combinations including nearly 50 disc-shaped washing brushes.

* Design of 6 inverters: 2 inverters to control the speed of 2 high-pressure fans, 2 inverters to control the speed of 2 disc-shaped cleaning brush combinations (nearly 50 brushes), 1 inverter to control the speed of 8 cleaning brush rolls, 1 inverter to control the speed of the rollers to automatically connect with the entire system of other equipment to form an automatic line.

* The machine includes 3 pairs of drying blades, including 1 pair of straight blades, 1 pair of cross blades and 1 pair of striped blades, so the glass will be dried super fast, helping the machine’s operating speed to be super fast and ensuring that the glass is absolutely clean and absolutely dry immediately after washing, ensuring strict technical requirements for raw glass before being put into the vacuum plating chamber for the production of mirrors, reflective glass and soft-coated low-e glass

* The machine includes 3 air knife clusters to support the washing compartment, including 1 cluster to prevent water from overflowing to the front, 1 cluster of high-pressure wind blades to push clean the rough washing part after 2 washing brush combinations with a disc-shaped washing brush to prevent water from overflowing into the main washing compartment, 1 cluster of high-pressure wind blades to push clean the main washing part after the main washing compartment with a roll-shaped washing brush to prevent water from overflowing into the drying compartment.

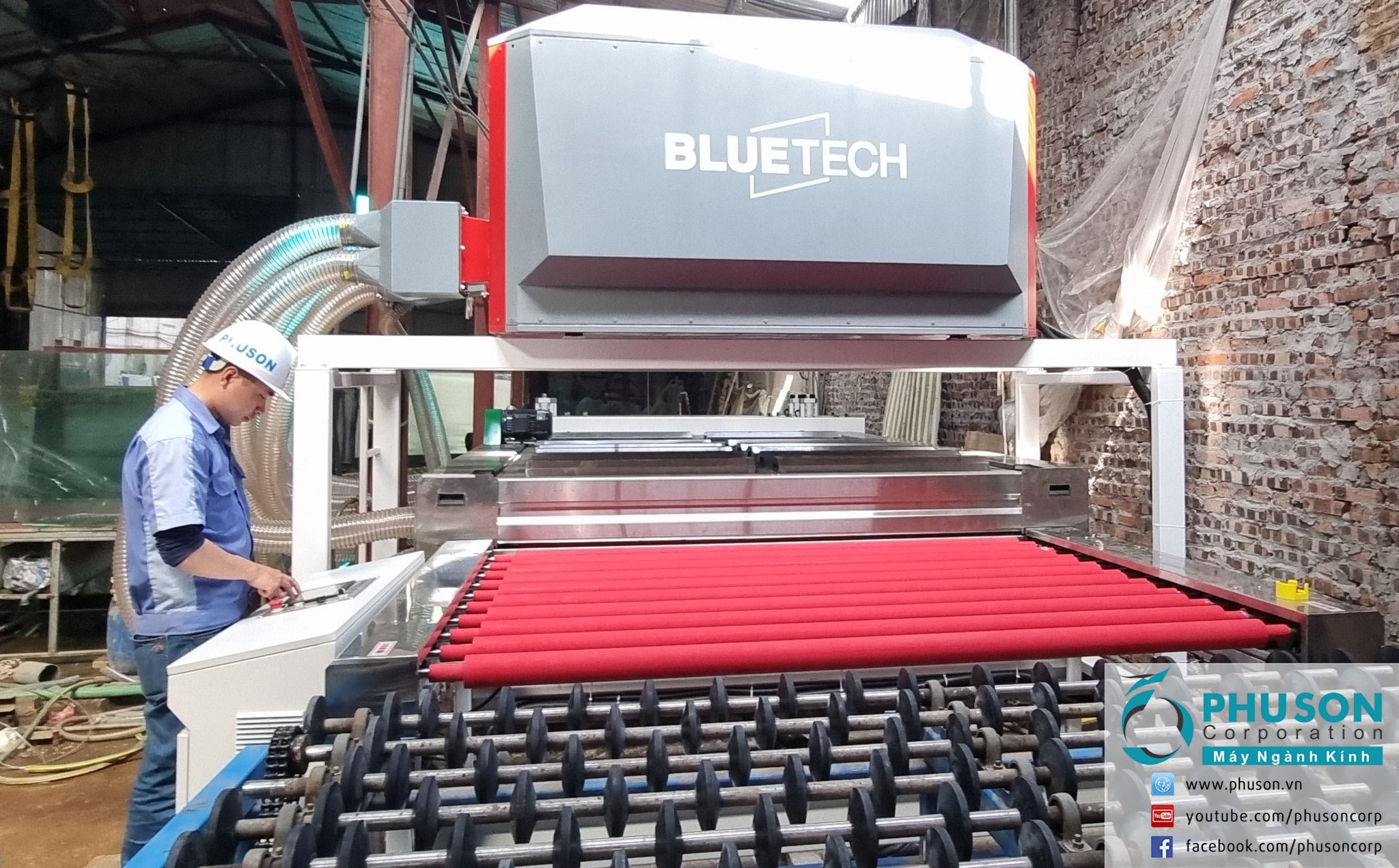

* Can automatically link to change thickness according to data from the double-edge grinding line with QR code or barcode shooting feature

* Has the feature of automatically closing the air vent and automatically turning off the high-pressure fan to reduce noise and save energy.

* The main structure of the upper and lower body pillow frame is made of a completely new generation of cast aluminum core system (no need to drill, or weld, which weakens the frame system and causes rust to the water source).

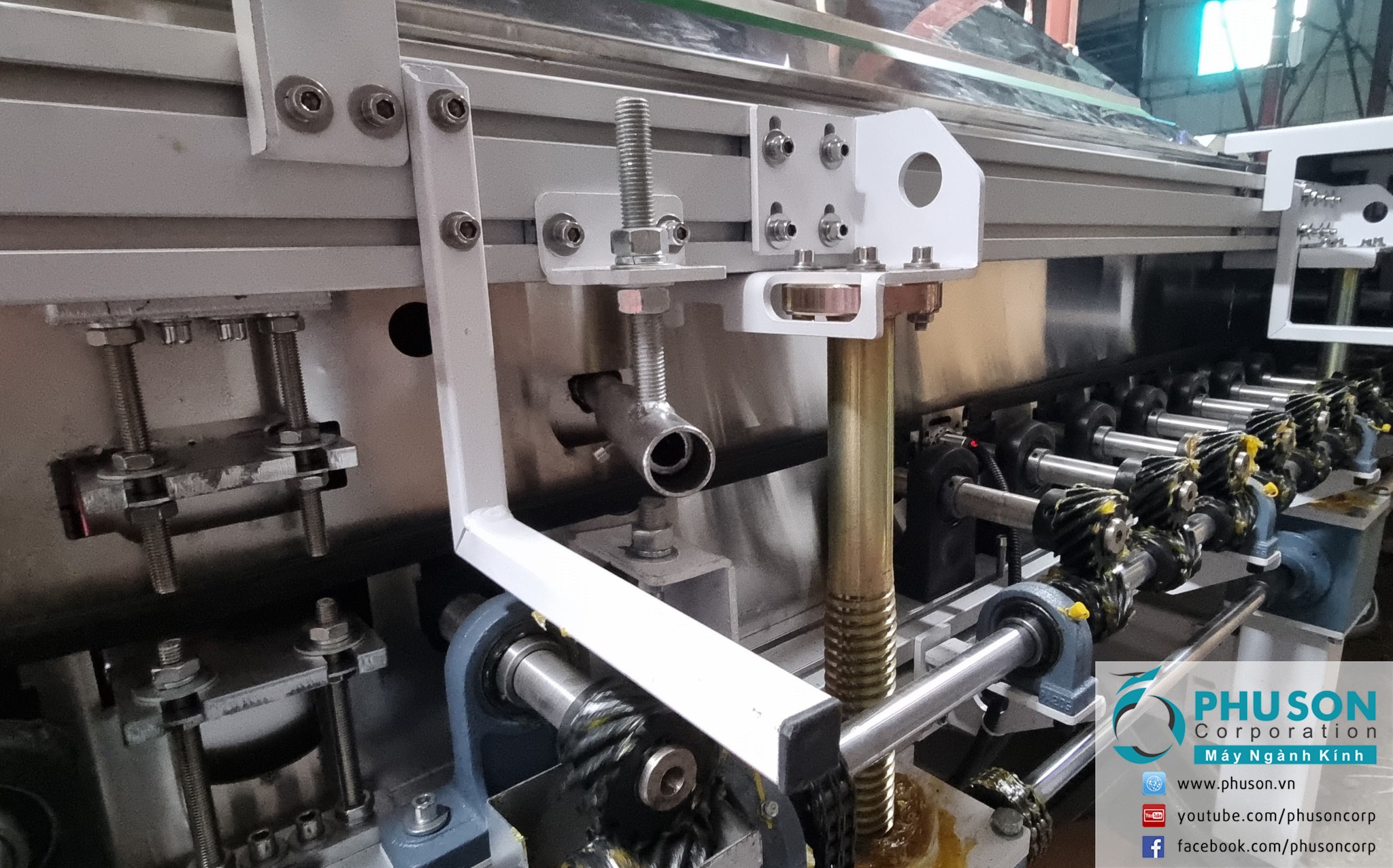

* The entire movement is by gears (not by chains so it does not dirty the water source due to splashing grease)

* The machine is designed to wash soft-coated Low.E glass with a specialized brush roll No. 4 and automatically lifts 3 rough brush rolls No. 1, No. 2 and No. 3 with a combination of nearly 50 disc brushes when washing Low.E glass and soft-coated solor control

* Has a structure that lifts the entire upper body up to 400mm for easy repair and maintenance

* Has a function of heating water and hot air adjusted through the liquid crystal screen, super fast washing, super clean and super dry

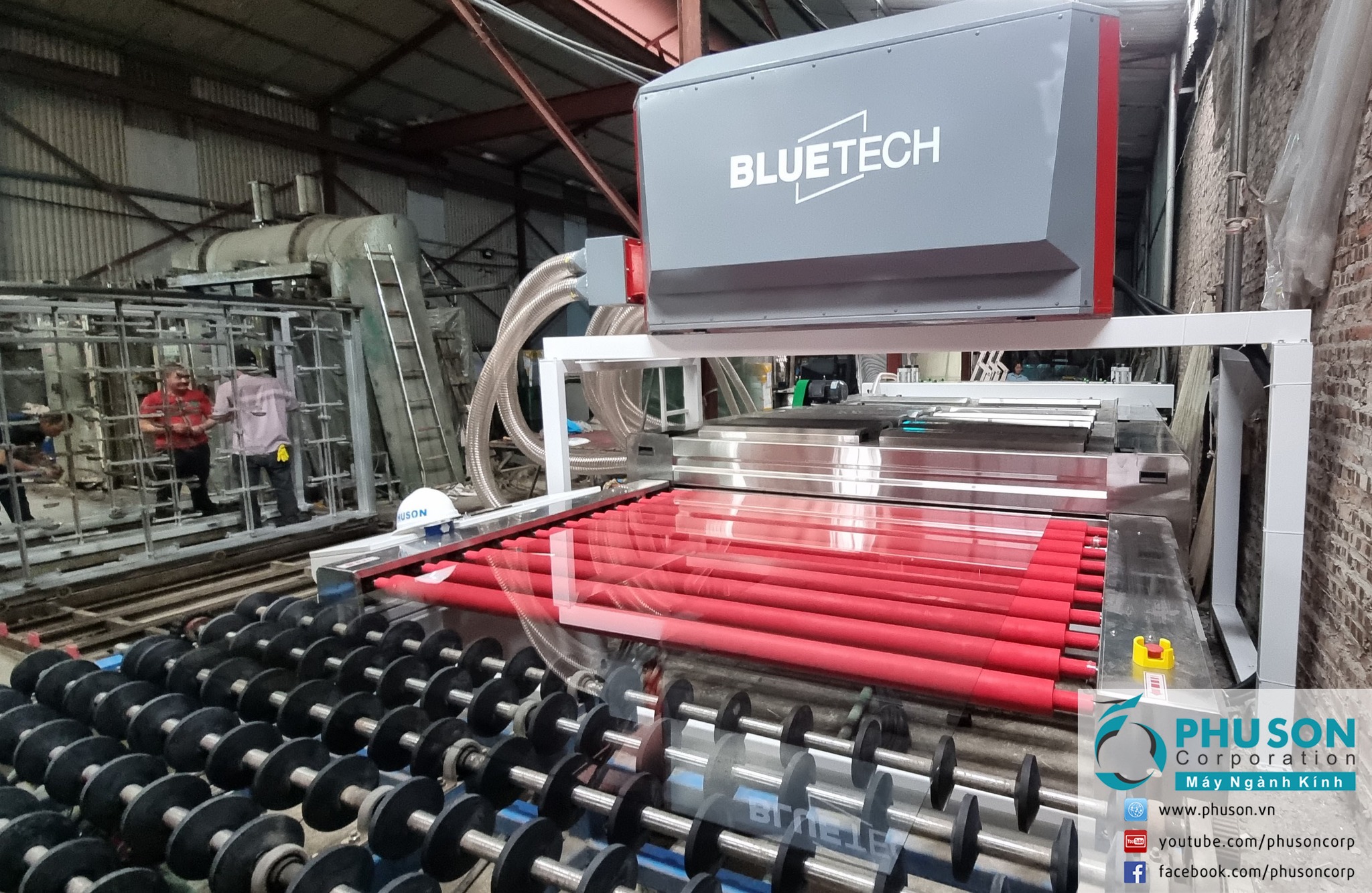

* The high-strength steel tripod frame folds to create rigidity, resistance and durable stability

* 2 disc brush combinations are placed on a separate frame from the body to prevent vibration for the machine

* There is a design of a water spray pipe box on the top and a submerged water pipe on the bottom so that all glass panels are exposed to water as soon as the glass enters the machine and before washing by 2 disc-shaped brush sets.

* The main structure of the upper and lower body pillow frame is made of a completely new generation of cast aluminum core system (no need to drill or weld, which weakens the frame system and causes rust to the water source).

* The structure of the machine base frame is made of thick, high-strength steel, which folds to help the machine operate firmly and last for many years.

* The entire movement is by gears (not by chains, so it does not dirty the water source due to splashing grease, except for the cross roller part that uses a pair of cross-shaped wind blades).

* The entire ball bearing is used with a new generation L-shaped foot structure, which helps to make the bearings strong, stable and durable.

* The scientific water-proof structure absolutely does not let water splash into the bearings, helping all bearings operate stably and last a long time.

* All parts in contact with water are made of stainless steel, and all components of the machine are of high quality, helping the machine operate at a fast, stable and durable speed