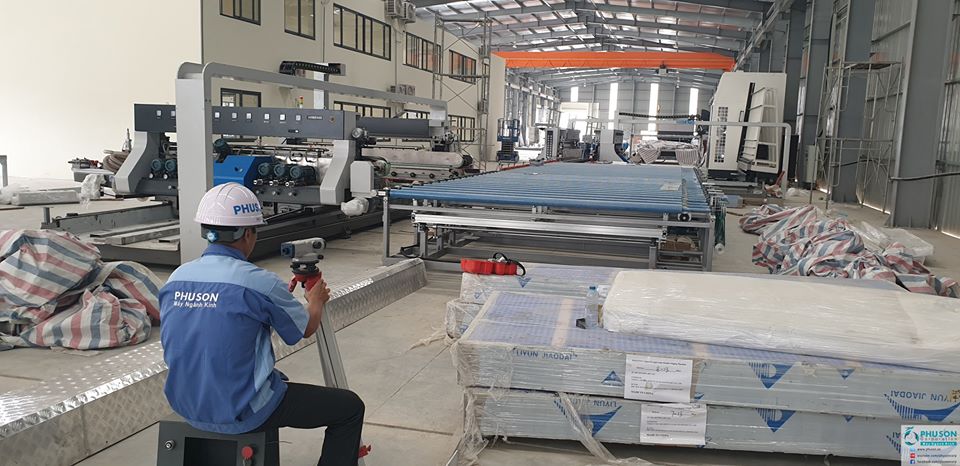

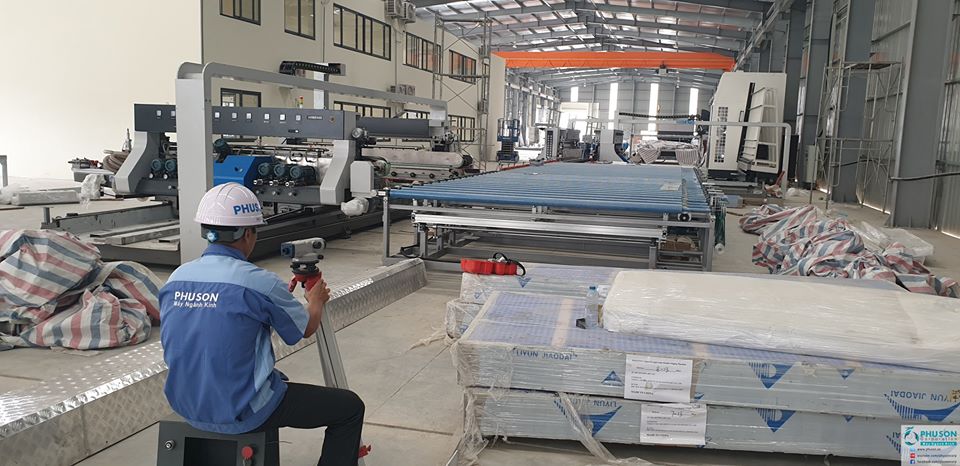

PHU SON Corporation HN installs an automatic low.e glass polishing line with a soft-coated solar control with barcode reader and a lot of outstanding technological features HISENG at VIGLACERA DAP CAU GLASS energy-saving glass processing factory .

The line is designed with completely new and modern technology:

- * 3 SCHINEIDER PLC

- * 2 SCHINEIDER screens

- * 40 ABB grinding head motors.

- * 6 servo motors + 6 SCHINEIDER drivers (the machine is equipped with 4 servo motors for conveyor movement and 2 servo motors for changing the width of the glass panels at an extremely fast speed – 8 times faster than normal) .

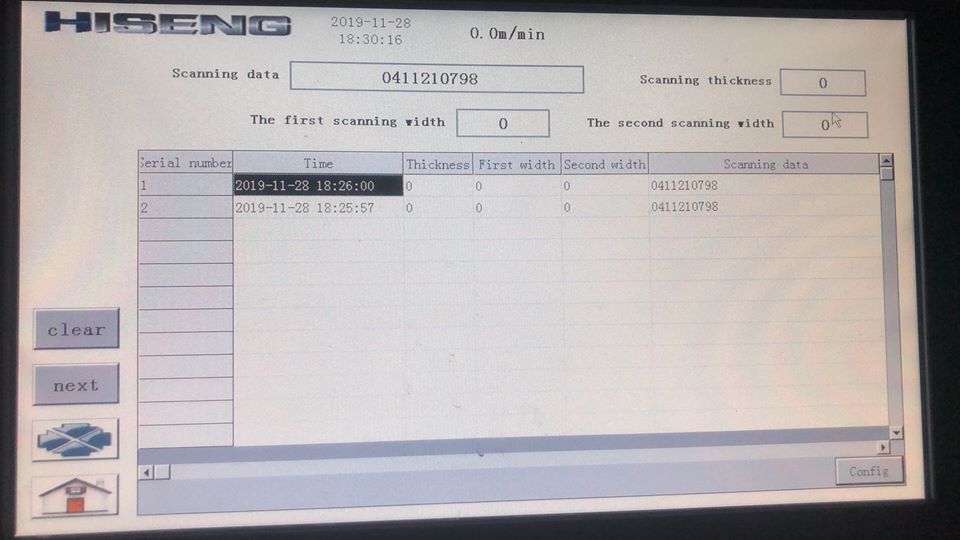

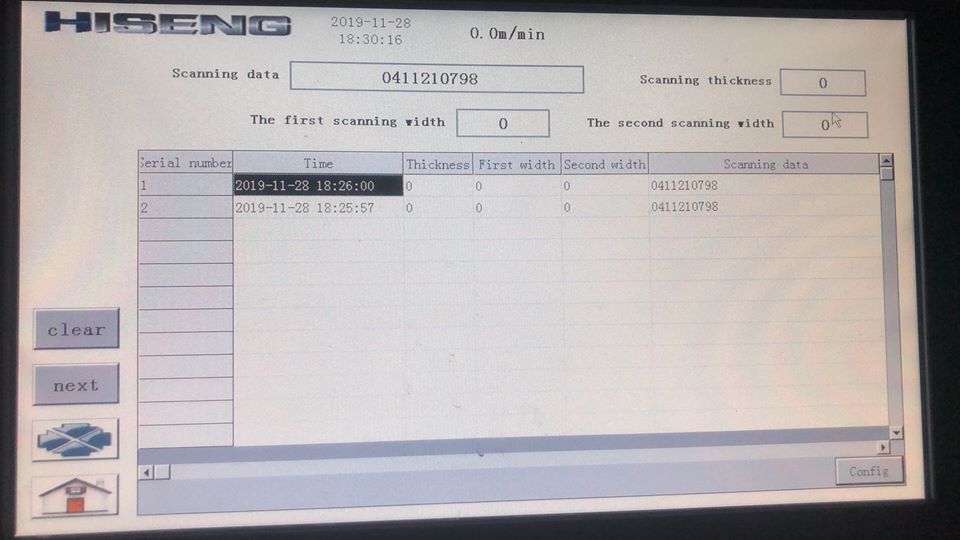

- * Wireless barcode reader helps the machine automatically receive production orders with the feature of automatically changing thickness, length, width, polishing or roughing completely automatically.

- * The central support is always automatically positioned in the middle when changing the width of the glass to ensure that the glass is always flat without human adjustment.

- * The above conveyor is specially designed to not scratch the soft coating of Low.E glass and energy-saving glass plating off-line.

- * Conveyor belt is designed to be very wide and very thick, special standards for industrial production, stability, precision and durability.

- * The machine is equipped with 4 suction systems to ensure no splashing of water on the surface of the glass plate when grinding, which helps to prevent the acidic water from adhering to the surface of the glass sheet, making it difficult to wash before toughening and keep the working environment clean and dry at the production area.

- * The machine is equipped with double grooving spindles and HIWIN sliding rails to ensure stability, durability and absolute accuracy.

- * All electrical components, electronics, centralized control cabinet connection system follow European standards – CE, ensuring high standards and absolute stability.

- *** The product has beautiful and sharp shadows evenly on all 4 sides.