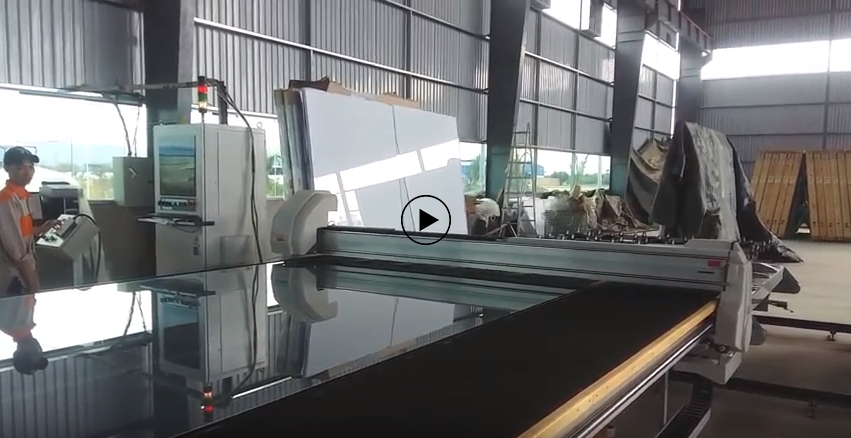

PHU SON Corporation HCM completed the installation and delivery of HISENG automatic horizontal glass straight edge polishing machine at TAM LOC PHU GLASS factory.

The machine is designed differently and top notch:

PLC control + liquid crystal display 20 ABB . grinding head motors

The movement of 2 pairs of conveyors by 2 servo motors + 2 drivers helps to ensure absolute accuracy in working speed and is convenient for connecting other automatic line-operated systems with the machine.

Horizontal movement by 1 servo motor + 1 driver is extremely fast and accurate to shorten the waiting time when changing the width of the glass.

Glass panel width max 4200mm, min 350x350mm

The supporting roller frame is always automatically centered when changing the glass panel width

The system of sucking and blocking water to the surface of the glass when grinding helps completely eliminate the possibility of acidic water on the surface of the glass and keeps the work area dry.

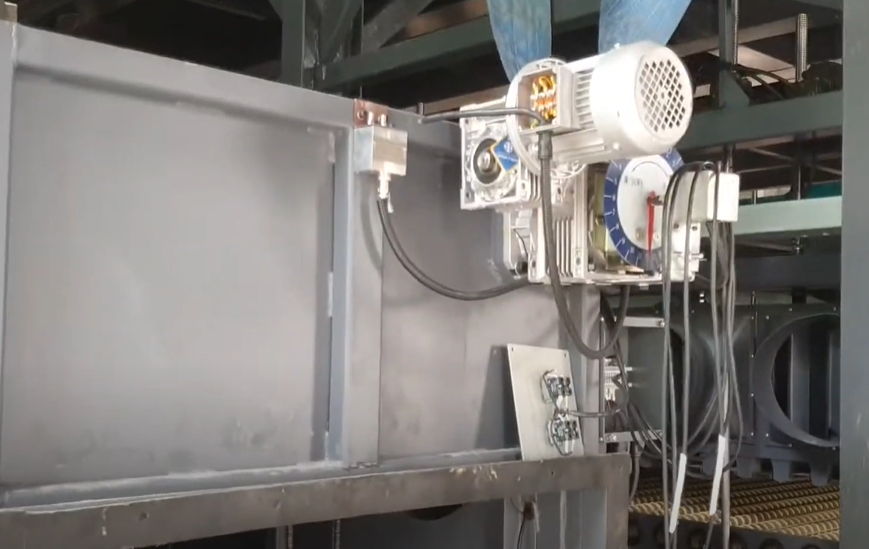

Double-groove spiral shaft for precise operation and long-term durability

The above 2 belt conveyors are specially designed for grinding Low.E glass and other energy-saving glass with soft coating and help prevent water from reaching the glass surface.

Electrical connection system and all electronic components according to European standards – CE.

The machine already has tools available for future investment needs to connect into a high-tech line, including an automatic table for measuring dimensions and thickness (machines 1 and 2 receive data and align at high speed). fully automatic).

The machine includes barcode shooting function: Barcode gun set integrates with intelligent control software to ensure consecutive receipt of work orders in order with multiple orders at the same time to automatically adjust both data. 2 machines and conveyor belt.

When the glass is in machine 2 and the following plates are of the same size, it will be automatically transferred to continuous grinding. 2 so that when machine 2 finishes grinding that plate, machine 2 will automatically adjust to change the width at a very fast speed and receive that glass into the machine immediately. When the glass is in machine 2, but a different size glass comes the back plate will automatically stop at the position in front of machine 2 and the next plate will not collide with that plate.

If the glass is in machine 1 but the front plate must stop at the transmission, the plate in machine 1 will continue to grind until the last sensor of machine 1 will stop completely automatically to maintain the most optimal working speed and Do not cause the glass panels to collide with each other.

The machine has 3 mechanisms to input data of work orders: (1) automatically by the barcode reader, (2) if the barcode reader or the transmission line fails, it can be entered manually through the command door of the code system. bar code, with these two data entry methods, the machine executes production orders completely automatically like the one in the above barcode, and (3) enters data through the manual command door like automatic lines through the bar code. Normally, the line will operate according to the usual mechanism that the glass will not automatically stop when the front glass is caught.

The most obvious advantage of the data system controlled by the barcode reader: (i) The machine automatically selects the polishing or rough grinding mode, (ii) Absolutely no confusion, (iii) saves time. , (iv) self-regulating system for continuous loading of goods and loading the glass panels together without the glass panels never hitting each other at any point on both machines and conveyors to improve efficiency. efficiency, optimization and science in production. When the glass is in the machine, it is not possible to adjust the movable pedestal to change the width of the glass panel to help the line operate completely safely.