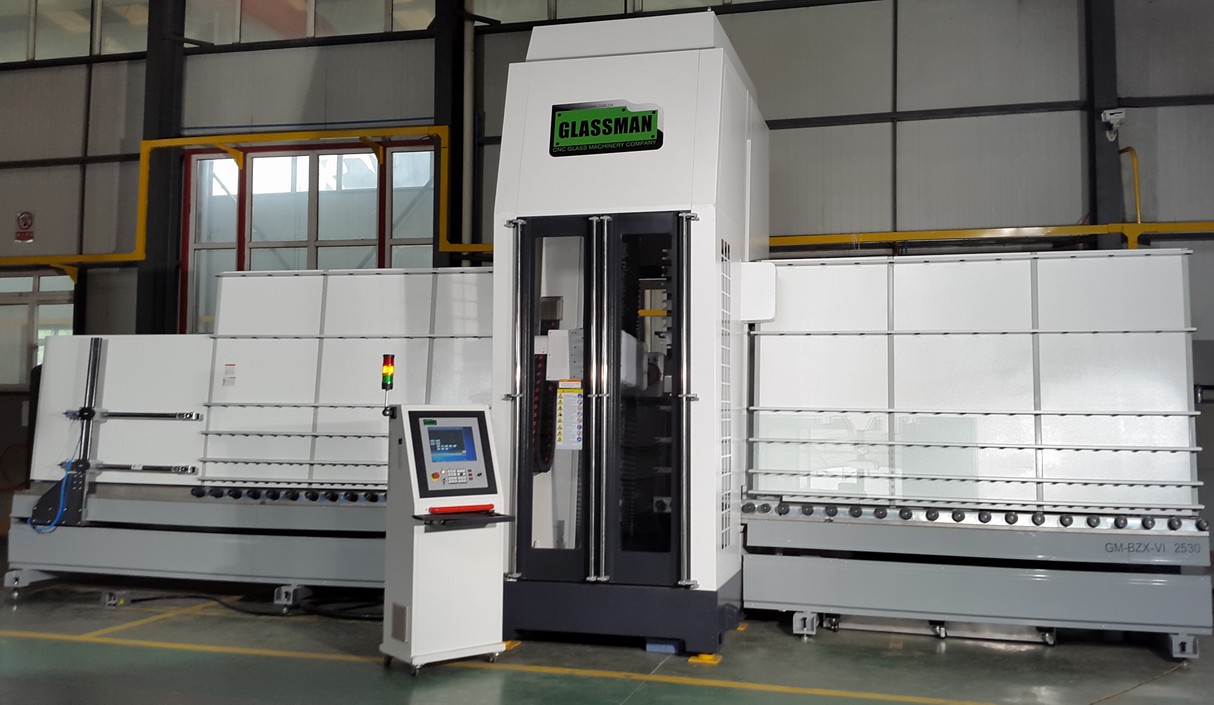

GM-BZX-VI is a CNC vertical working center with high technology. It can perfectly perform complicated working in short time, and the processed sheet is of high level which realized to obtain a CNC machine with smallest investment.

The CNC working center applies numerical operation and control system to achieve dynamic management of each axis and speed precision control. So the shape is of precision and the processed sheet is of high quality. It is a CNC vertical drilling, edging and milling machine to process simple and complex drawing and featured by the most advanced technology. It is a solution to the requirement on processing precision, high speed and ease operation.

GM-BZX-VI can automatically process complex drilling, milling and arrising function on large flat glass. When the glass was loaded on the feeding rack, the machine begins to execute the prepared program on drilling, milling, arrising etc.

The flexibility of the control system can meet the requirement of different products, the whole work is finished automatically. This machine is suitable to process structural glass (Frameless door, glass curtain wall etc.) The function including:

Drilling by two opposite spindles; Milling by single router; Arrising

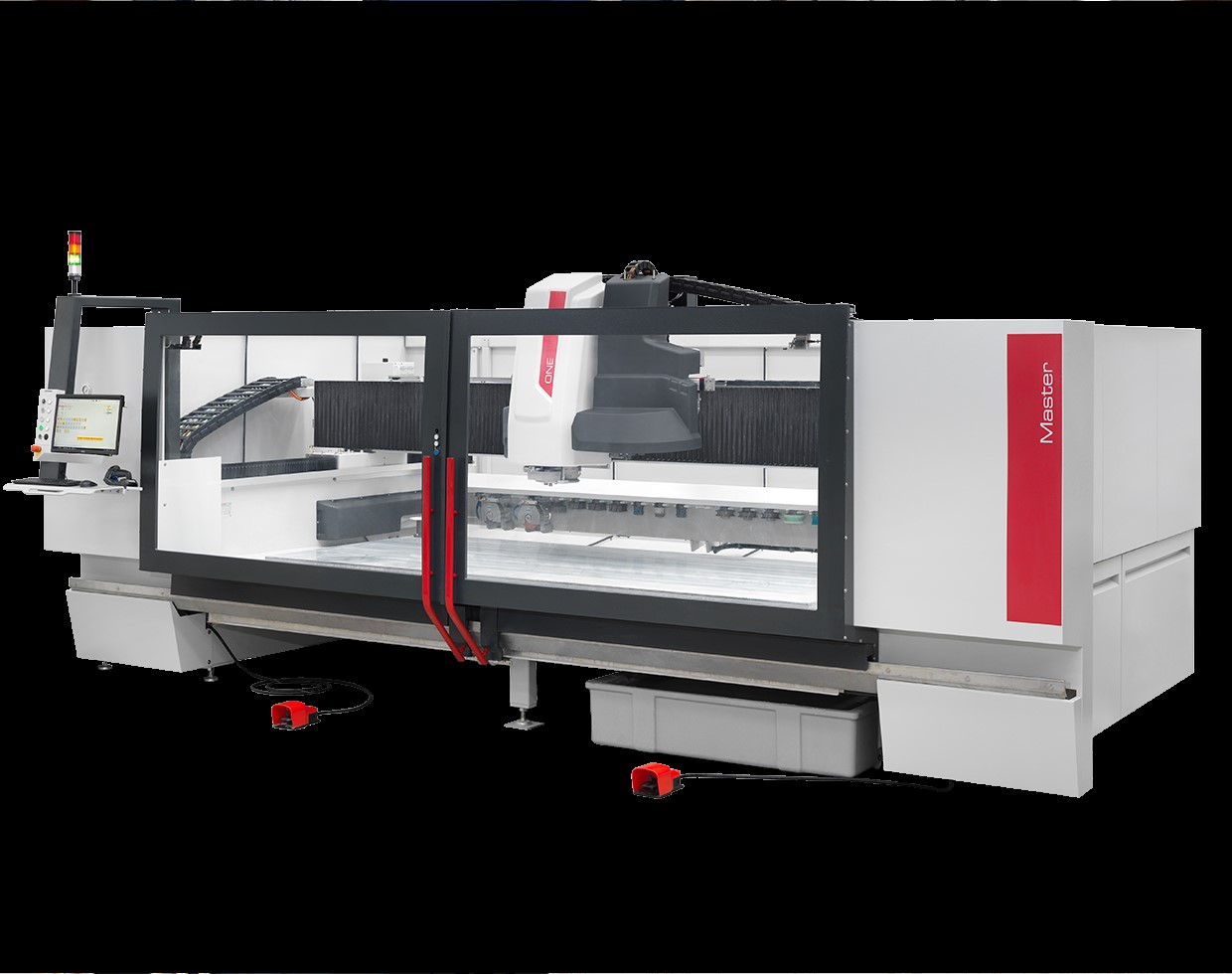

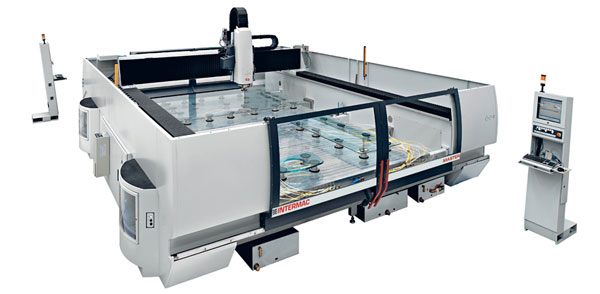

GM-BZX-VI is a vertical glass-working machine; with all the main part protectively covered. The structure is convenient to load and unload the machine and occupied less area. It also can reduce the obstruct and easy to process the glass sheet, or even advantaged to the coolant water system.

The main part is welding structural steel, driven structure of Y and V axis is installed on the double bridges. X, Y,V, Z, W linear axis are driven by high precision ball screw and slip on the linear slide way. X -axis controls the glass forward or backward, Y and V axis control the up and down movement of the two Spindles, Z and W axis controls the spindle to take or release the tool.

Advantage of this structure: High acceleration thanks to the rigid structure; High-quality production thanks to the high-precision Taiwan ABBA ball screw; With low abrasion, the machine maintains high quality after using many years. The motive parts are lubricated by the central lubricating part oil pump (Brand: Zhejiang Liubian). Guide shed are applied around the main part of the machine. Standard is made from cold plate plastic spraying frame or PC board with Alumium frame.To observe the working conveniently, two doors are provided in front and at the back of the guide shed. (Please look at the following pictures for your reference)