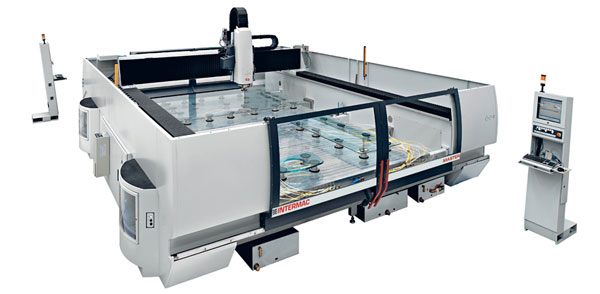

Master 53-55 and 63-65 represent the development of the new range of Intermac work centres to satisfy those who need to work without dimensional limits. These machines are the solution to work with ease and productively structural glass, jumbo size sheets and big size furniture (tables, doors, etc.). Ideal for double station working.

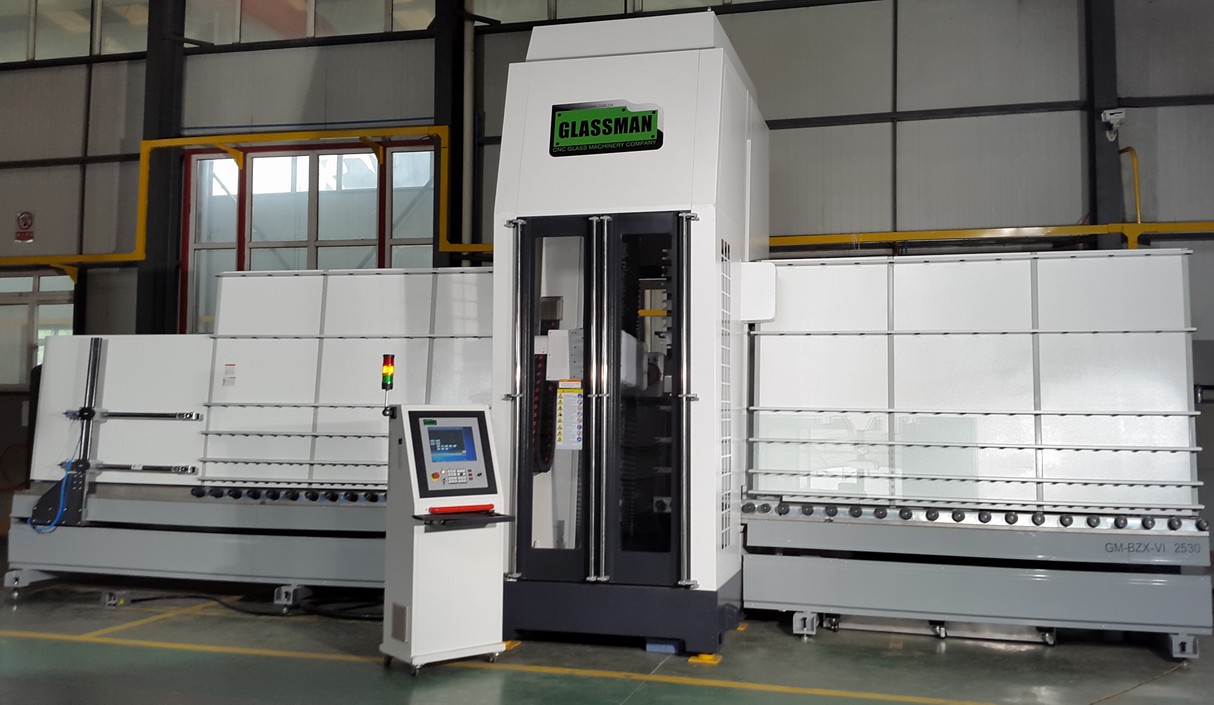

The new electro-spindles with a liquid cooling closed circuit are provided with a control system of the rotating couple and speed in order to assure the best processing quality Master 53-55 and 63-65 are equipped as standard with double machine controls placed at the two sides of the work centre to offer maximum comfort to the machine operator. In the picture special configuration with front cabinet on the right side. In the lay out the standard configuration.

Intermac’s world wide success is the result of the long tradition, technical knowledge, man power and technology employed in the Research and Development department, which are focused in always finding new and more advanced solutions.

Designed for the bestThe quality of Intermac’s products start at the design stage, where the most advanced CAD modelling systems simulate static and dynamic torque generated during machining operations, showing how to improve the machine. High quality components, materials and numerous quality tests performed on each machine guarantee to our customers a highly reliable machine.

Tools presetter through a visual device (opt.)The presetter positioned next to the cabinet and directly connected to the software of the machine allows to update in real time the tools parameter, enables to set the whole tools of a sequence through a camcorder. Grants great speed, precision and eliminates the necessity to make test before starting the production of the first piece.