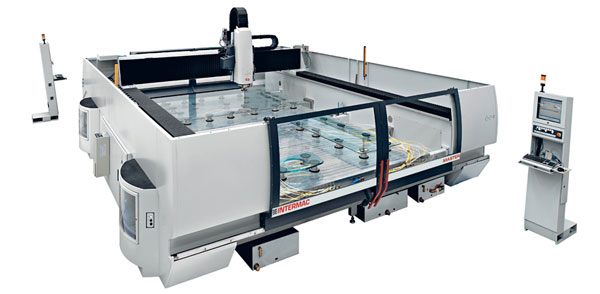

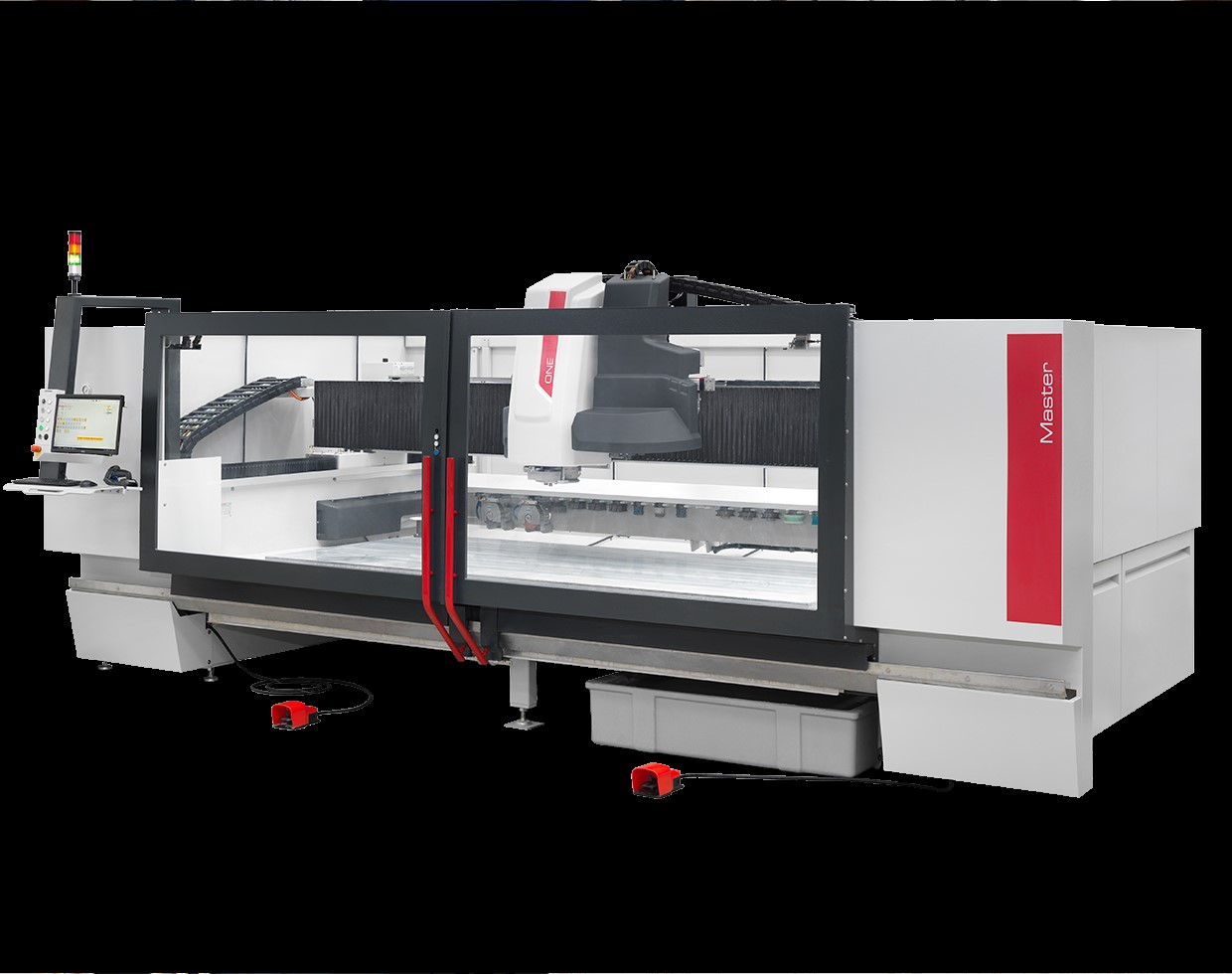

Master 33-43 represent the last evolution Intermac in the world of 3 axes work centres. These machines are addressed to those companies that intend to develop their production capacities with an highly reliable machine with an excellent quality-price ratio. The possibility to equip the work centre with a fourth axis further extends the flexibility of these machines and allow them to adjust to the most varied productive needs. The machine control is carried through a commercial Windows PC thus granting ample connection and ease of use.

PC based IWNC numerical control (Intermac Windows Numerical Control)

PC based IWNC numerical control (Intermac Windows Numerical Control)

Master 33-43 are equipped with the IWNC numerical control integrated into a personal computer with a Windows interface. The advantages of this solution are evident and introduce a new standard in the design of this type of machine. The use of a PC with Windows XP operating system is extremely simple and intuitive for the operator and provides full connectivity with commercially available network systems and optical/magnetic supports. The PC is supplied complete with CD-ROM drive, modem and network card, 15” colour monitor and Windows XP operating system. The PC modem and teleservice software enables remote diagnostics and software. It’s possible to connect a webcam to the PC, to save and transmit in real time to the service department, instant images of some details of the machine.

Operator interface

The new operator interface in Windows XP is simple and user friendly. It allows to begin the processing schedule in order to grant the positioning optimisation of the pieces to be processed. The operator interface also allows to quickly and simply enter the various programs which are in the control unit, such as the origin management, the tools management and the daily production statistics which can be useful to calculate the machine’s productivity. The operator interface is completely integrated with the drawing and programming softwares such as ICad, ICam, IDoors and with the various application softwares that can be installed on the PC on board of the machine. Extremely important is the possibility to perform the processing, programming and the personalization of tools parameters and machine’s data while the work centre is working, totally avoiding the passive time still present in the machines of our competitors.