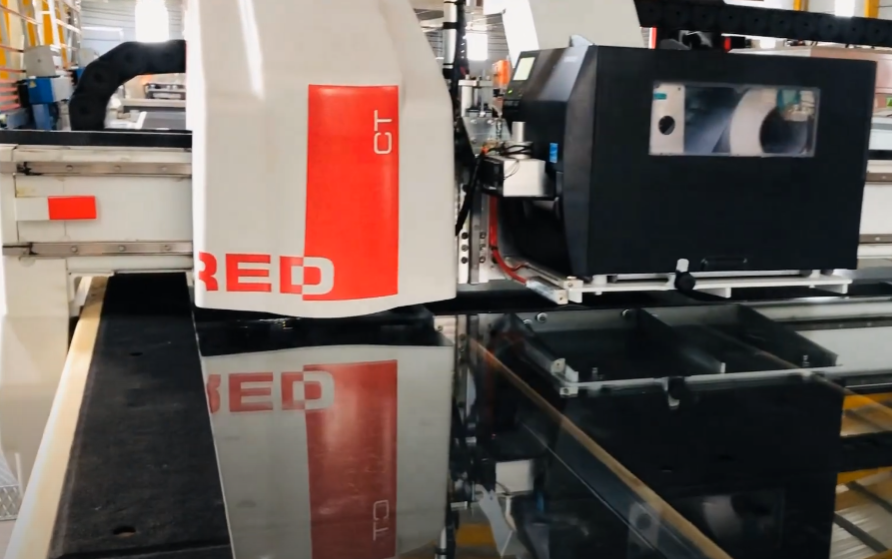

Experience the mechanism of operation technology of smart glass grafting robot, fast working speed and absolute accuracy on all 4 sides of the automatic glass production line of CHAOYANG high-class laminated glass at RICCO GLASS factory. .

CHAOYAG grafting robot is designed with super intelligence and “substance” on every detail of components, structures and operating principles:

* Conveyor motion design with 3 compartments independently controlled by 3 motors and 3 inverters helps to maximize the production capacity while ensuring the glass panels never collide from the machine. Wash to the positioning chamber, compartment compartment, transition chamber and heat press.

* Smart positioning structure creates right angle with moving side with magnetic sensor and automatically adjusts the final stage speed to reach the flip point so that the glass is stopped exactly and the right positioning point perpendicular to 90 degrees.

* The system of robotic arms up and down by 4 hands vertically at 4 corners, lifting and lowering by phitong Airtac with high capacity and structure of robot arm frame with cast aluminum core helps lift the glass plate weighing nearly 1 main ton Absolute body.

* Glass-driven robot movement with YASKAWA servo motor & driver, sliding rail guide and gear-driven motion according to the sliding principle of CNC cutting machine, fully automatic control via PLC and liquid crystal display Helps create paired glasses with perfect accuracy on all 4 edges.

* The design of multiple vacuum bowls with fine-tuned sensors and springs and soft rubber sprinklers helps to assemble soft, low-coated glass panels or brittle but not fragile glass panels like normal equipment.

* Design of automatic PVB film slitter with 3-reel independent remote control.

* The robot frame is designed with a strong and strong industrial frame structure system that ensures no shaking and long-term stability so that the glasses are always guaranteed to pair correctly.