- * The machine is equipped with automatic labeling features that contain barcodes or QR codes with Low.E plating coating function (similar to the ones previously provided to EUROWINDOW factories and factories. box glass expert with the material is Low.E glass covered with a brush) and many other useful features that are first introduced in Vietnam.

- * 3-axis design machine, C-axis completely independent rotation unlimited for fast cutting curve (conventional machines will not have independent C-axis design, so when cutting the curve will run slowly and the cutting head will being dragged down to the glass, not automatically rotating according to the cutting request).

- * The machine has the function of fully automatic printing and labeling containing the contents of the production order, logos and trademarks of glass processors, customer names or codes, order characteristics, bar codes or QR codes. (The machine has the function of blowing out the powder between the glass panels before gluing to make sure the label is fastened to the surface of the glass).

- * The machine has the function of grinding the low.e plating layer in the form of a grinding wheel or brush

- * The machine has a 6-point tool change center that makes it possible to replace the cutter according to the thickness of each cutting order and according to the requirements of straight cutting or bending on each glass plate completely automatically.

- * The machine can cut plotter glued on the glass so the processor can cut any sophisticated pattern, then peel off the negative part and sandblast or process with chemicals to form complete glass art works. perfect.

- * The machine has an automatic belt that accepts the glass from the glass feeding robot and automatically converts the glass to the glass separator table, creating a fully automatic line of glass loading-cutting-breaking.

- * The machine has a copy function that helps the cutter copy the pattern of any product and then reload the cutting style so that the finished product cutter is 100% true to the sample product ordered by the customer.

- * The machine has a positioning at point 0 and automatic positioning with Lazer so that it can place the glass sheet anywhere on the cutting table to be able to accurately shape the cutting and help the 2-layer glass cutter to be accurate when cutting face 1 then move and flip section 4.

- * Includes Iedit optimization software package, sticker creation software (with tools available for glass and logo design by glass processors, customer names or codes, order characteristics, barcodes or QR code, software to import data from Exel file or Text file format).

- * Machine made in Italy.

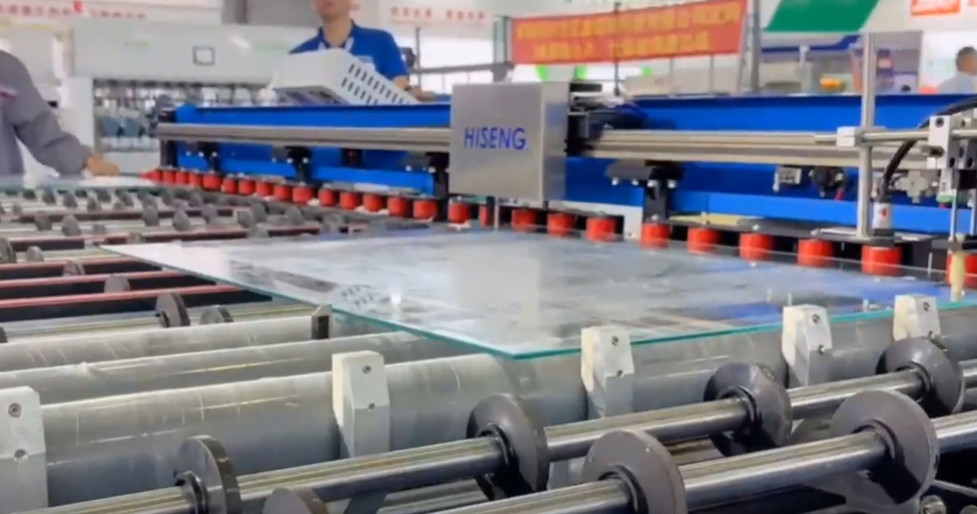

61 CT-RED glass cutter at VIGLACERA energy-saving glass factory

PHU SON Corporation HN completed the installation and technology transfer of large-format polymorphic CNC cutting machine with many outstanding features INTERMAC Genius 61 CT-RED made in Pesaro – Italy at the energy-saving glass processing factory of the Company. Viglacera glass erection limited company.