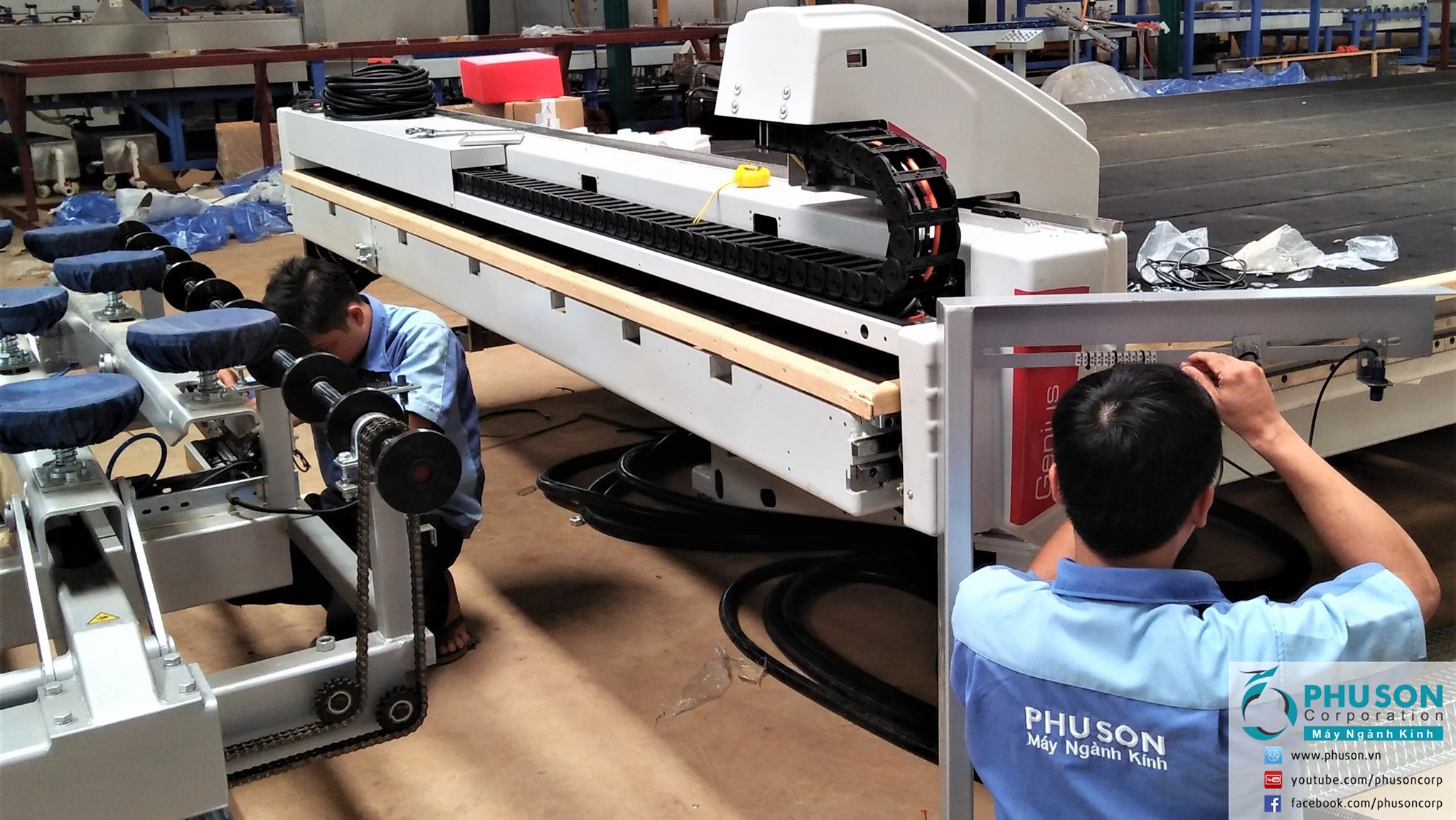

PHU SON Corporation HCM installed the second automatic Loading-Cutting-Breaking line of INTERMAC made in Italy at VIKING GLASS factory

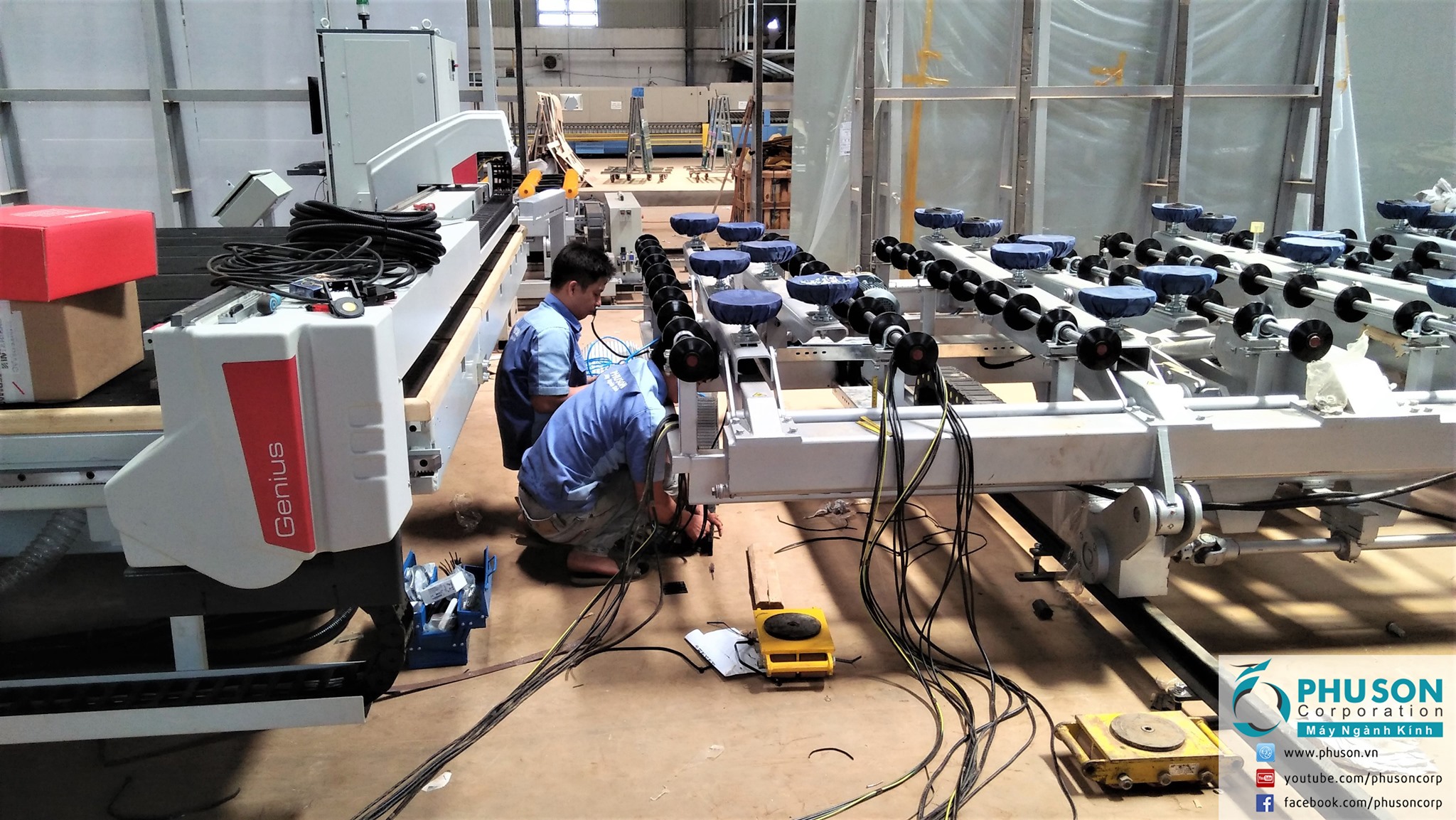

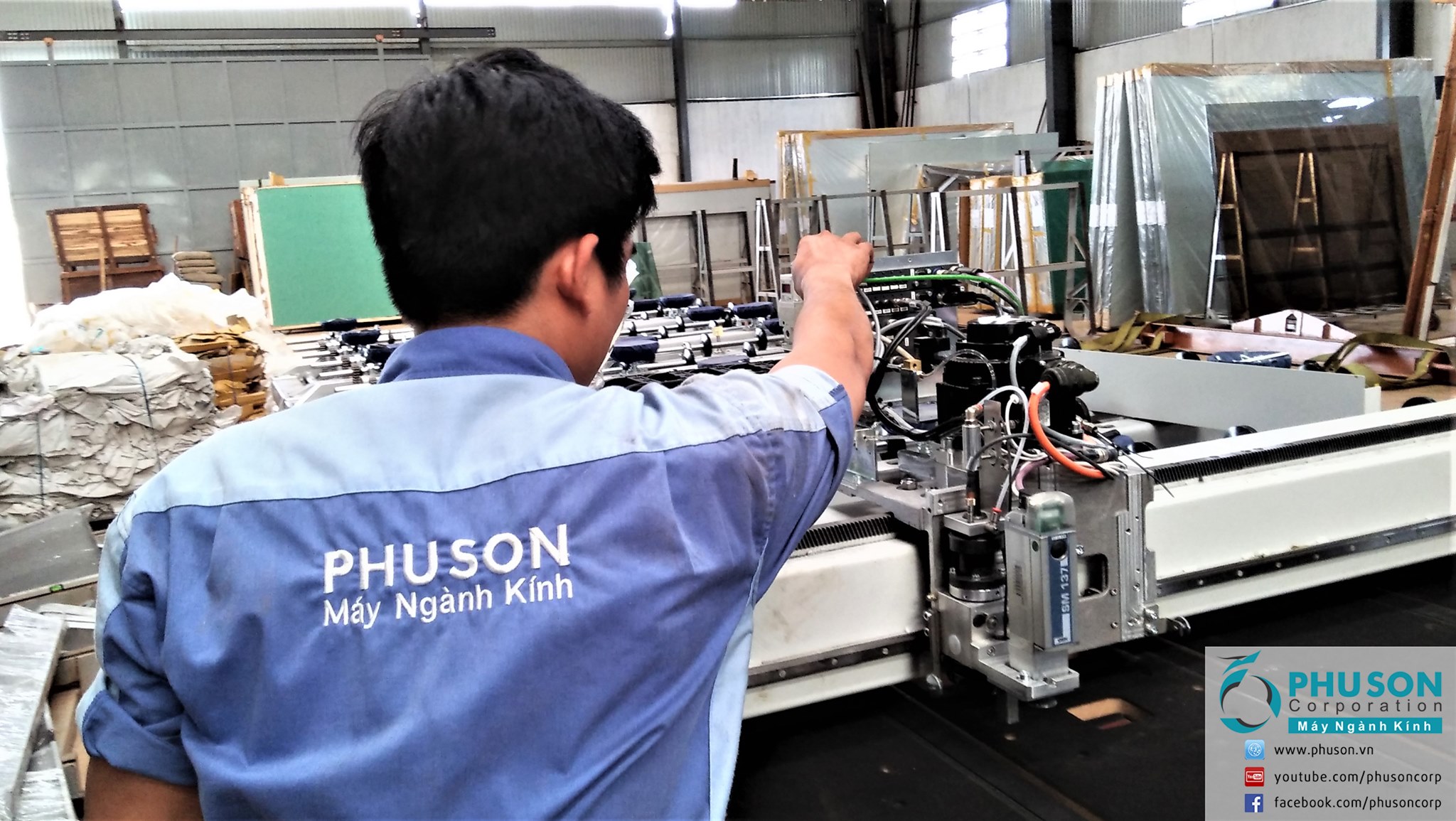

Having a strategic partnership with INTERMAC Italy since 2005, PHU SON Corporation has been completely independent in doing the installation, trainin, technology transfering and after-sales for hundreds of Intermac lines throughout the provinces of Vietnam successfully over the past 15 years without the presence of engineers from manufacturers

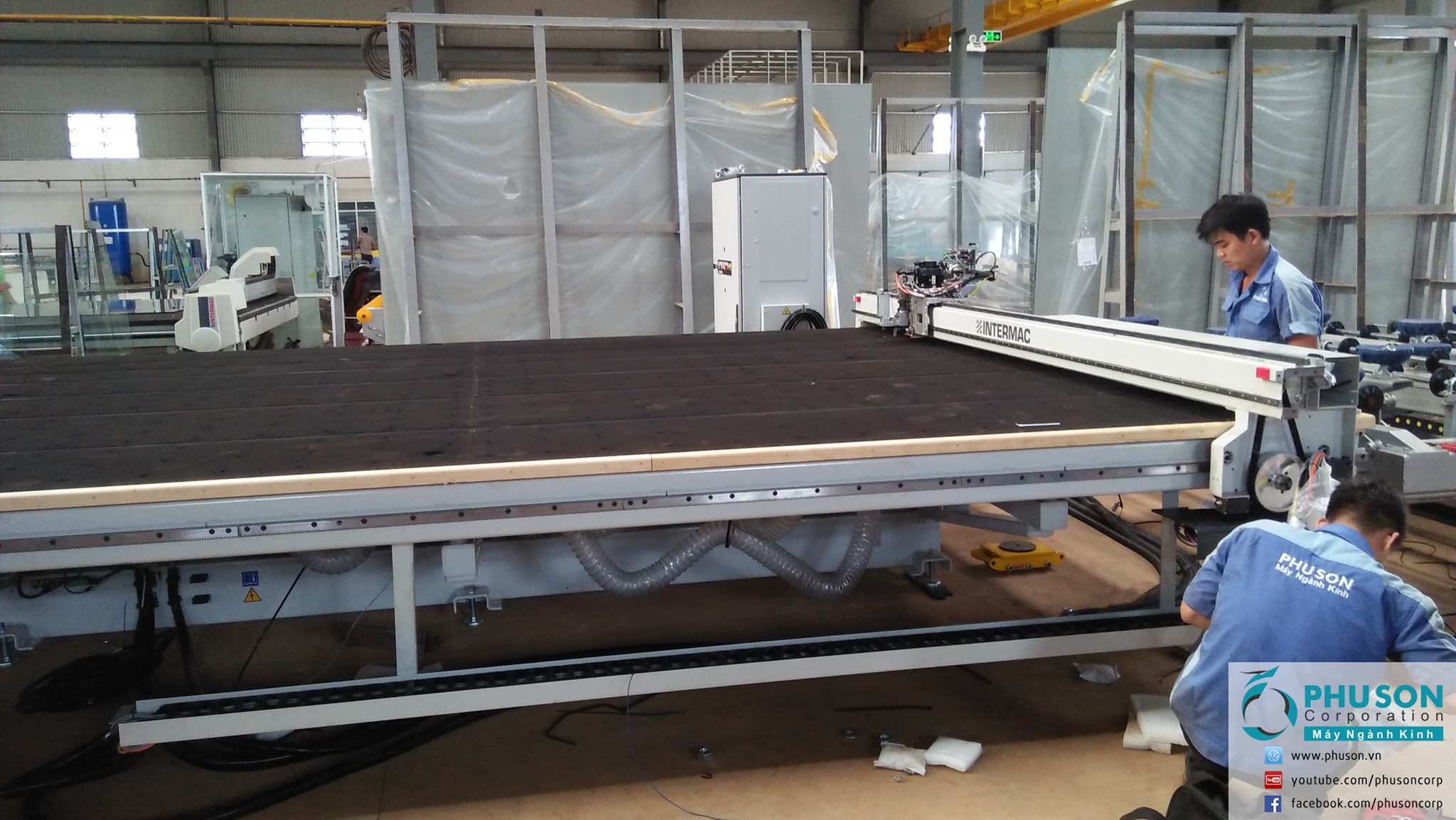

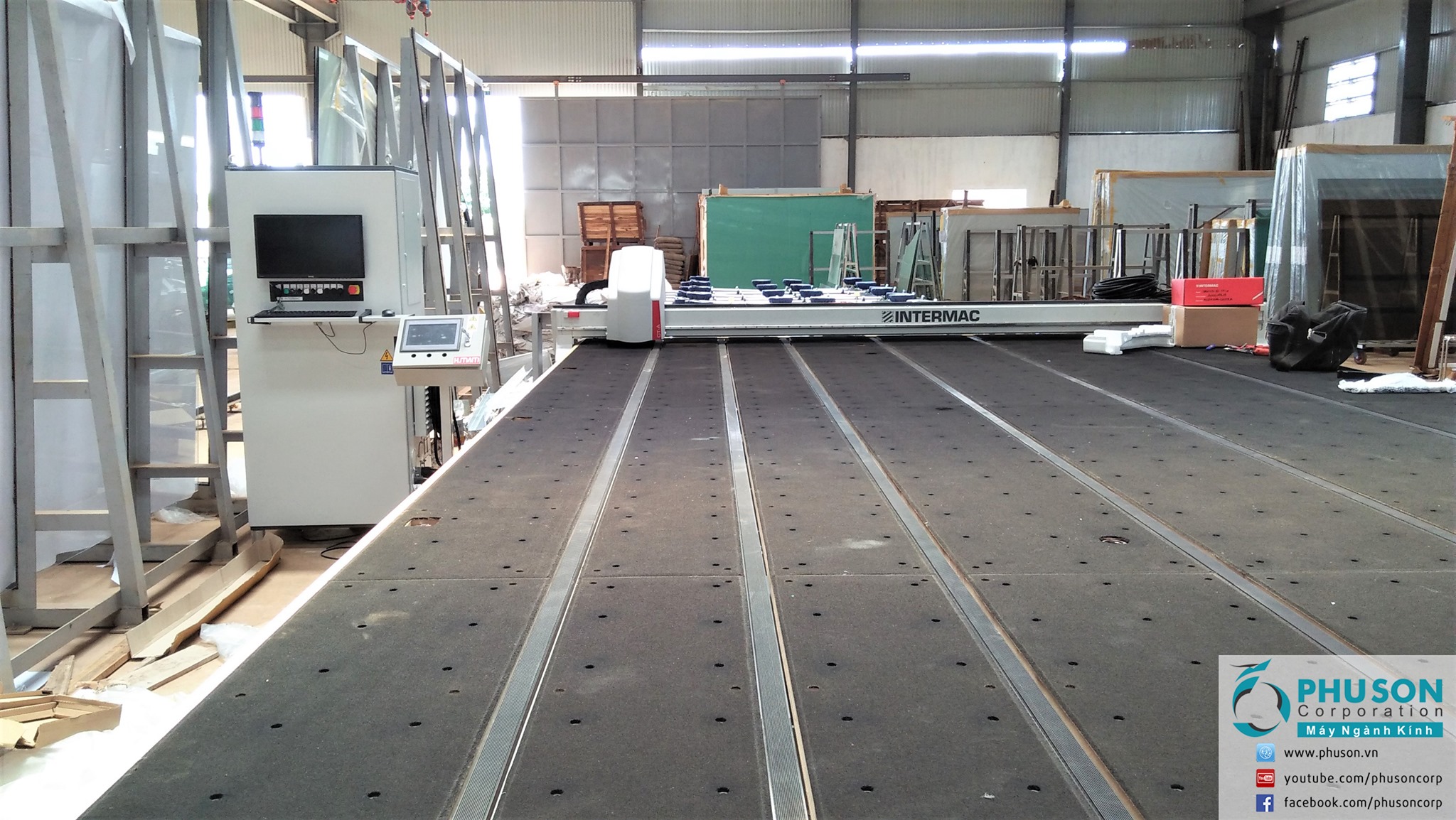

INTERMAC Genius 61 CT-A CNC glass cutting machine includes these outstanding features:

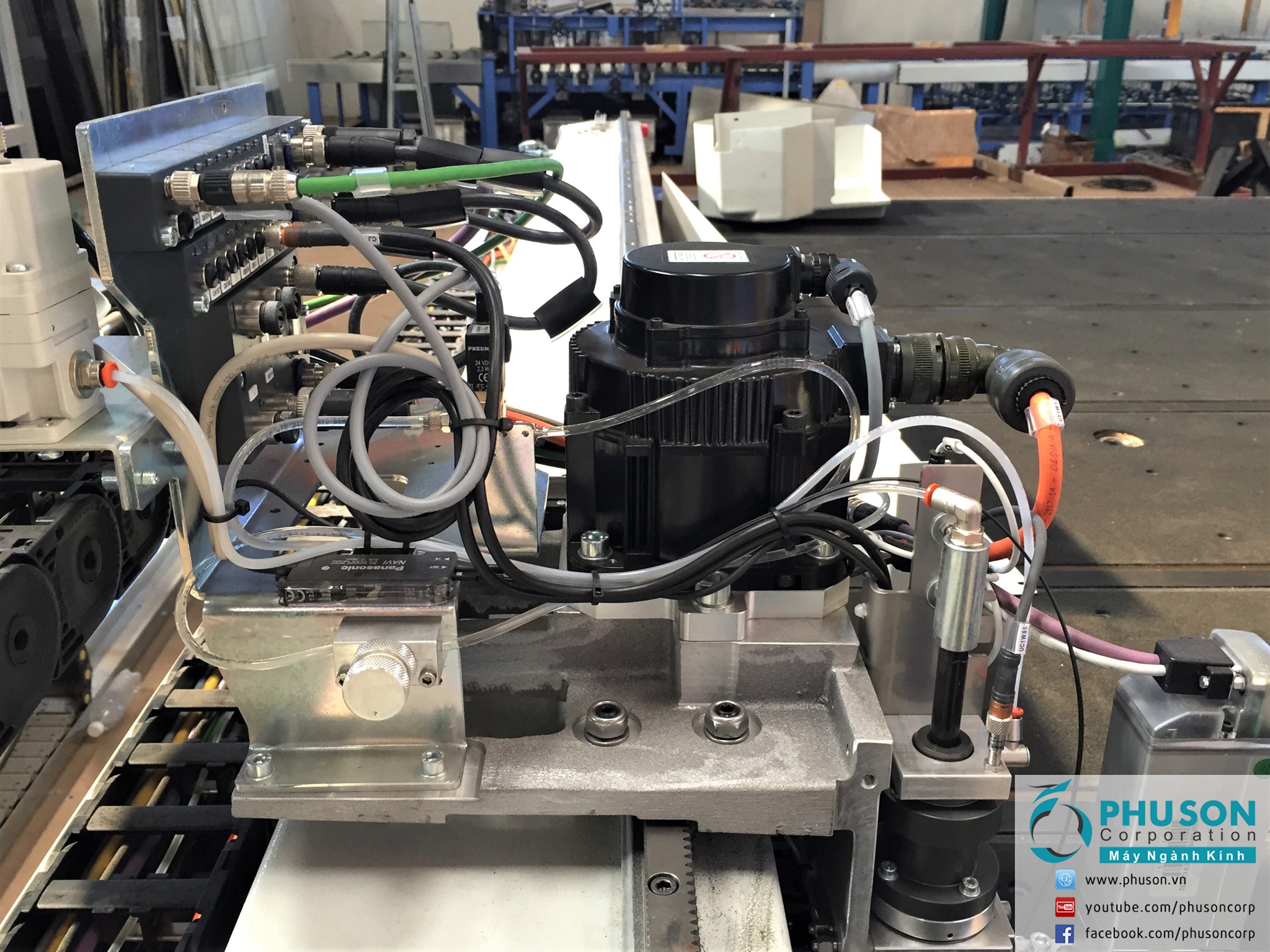

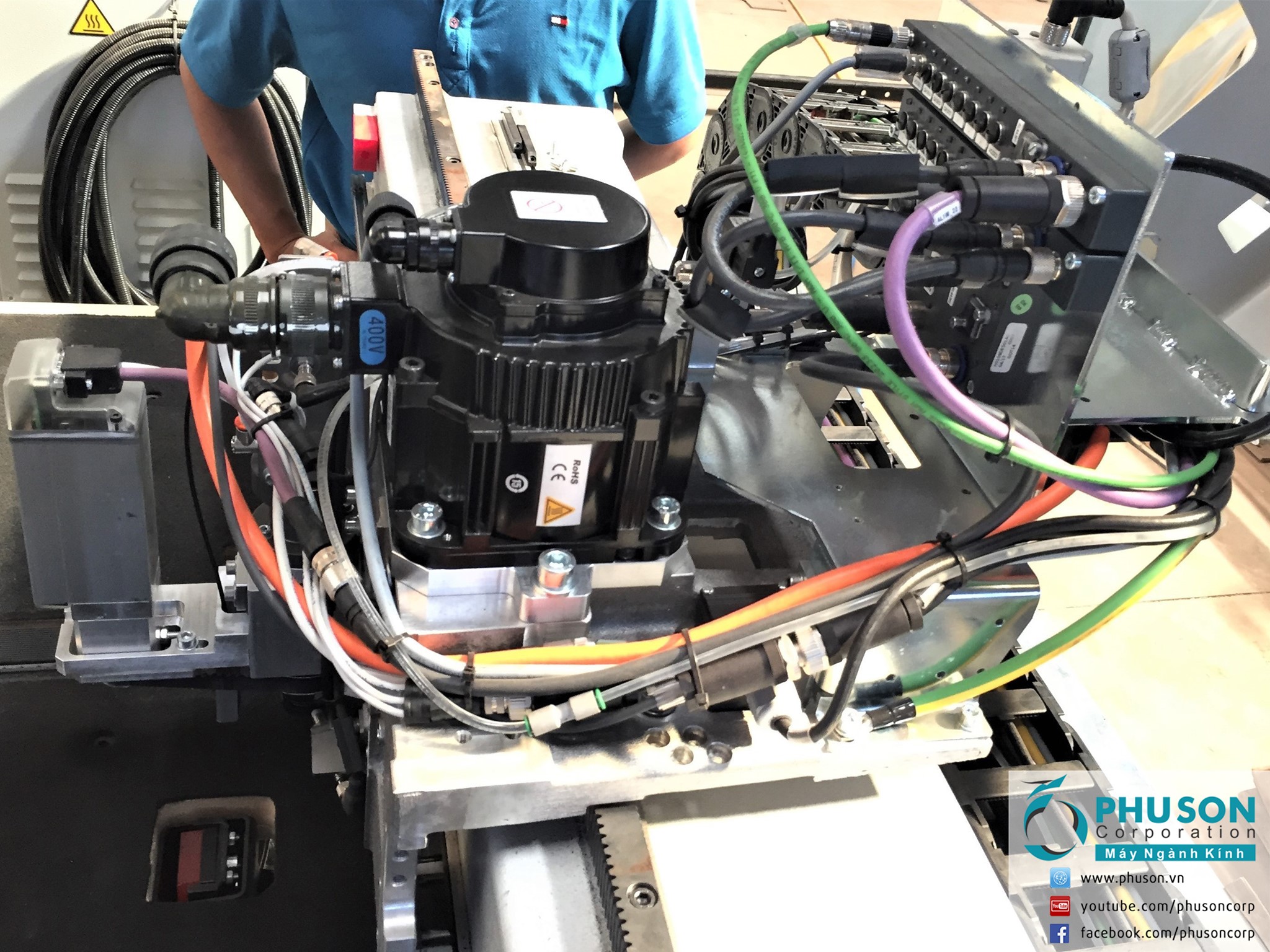

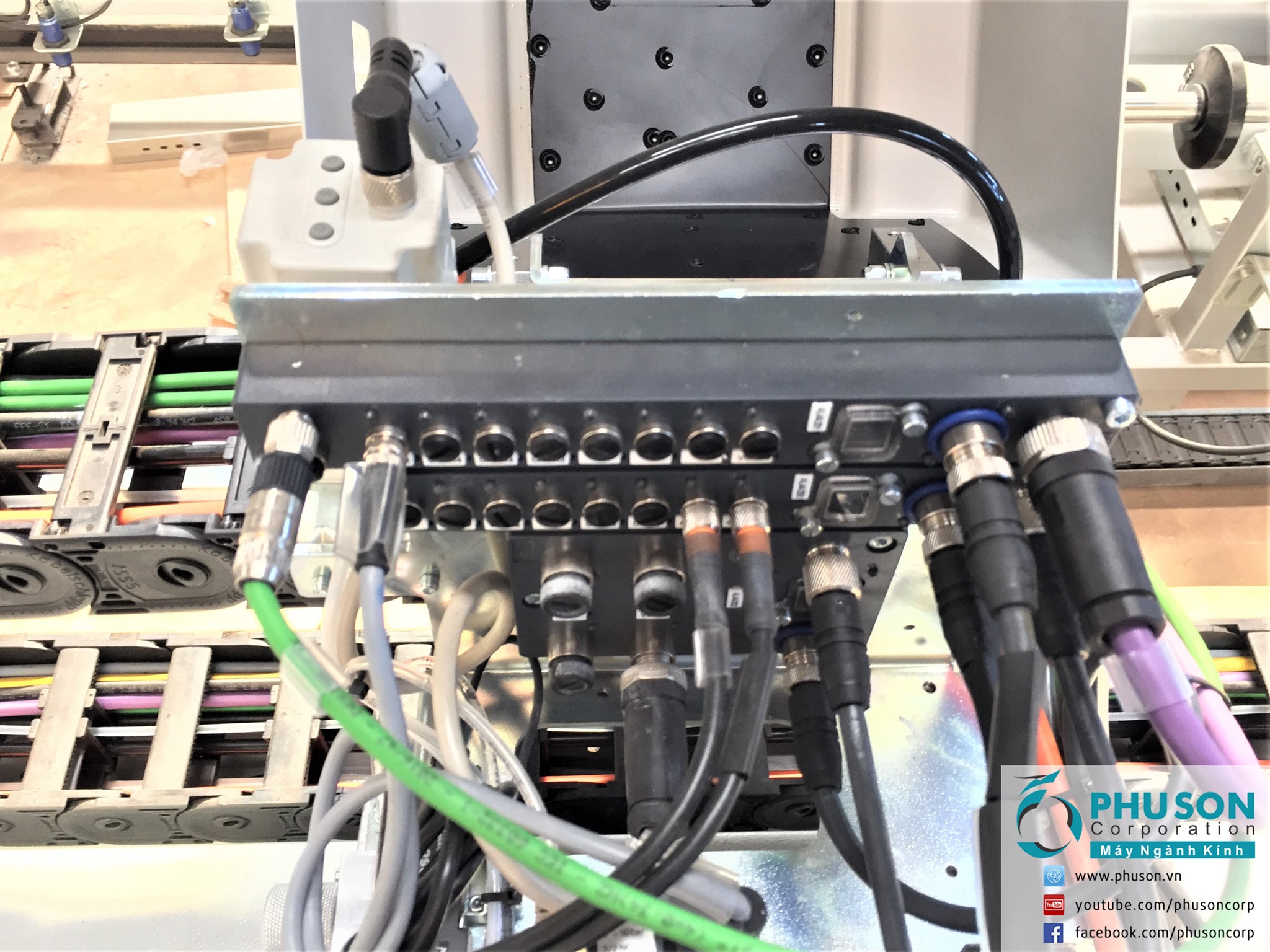

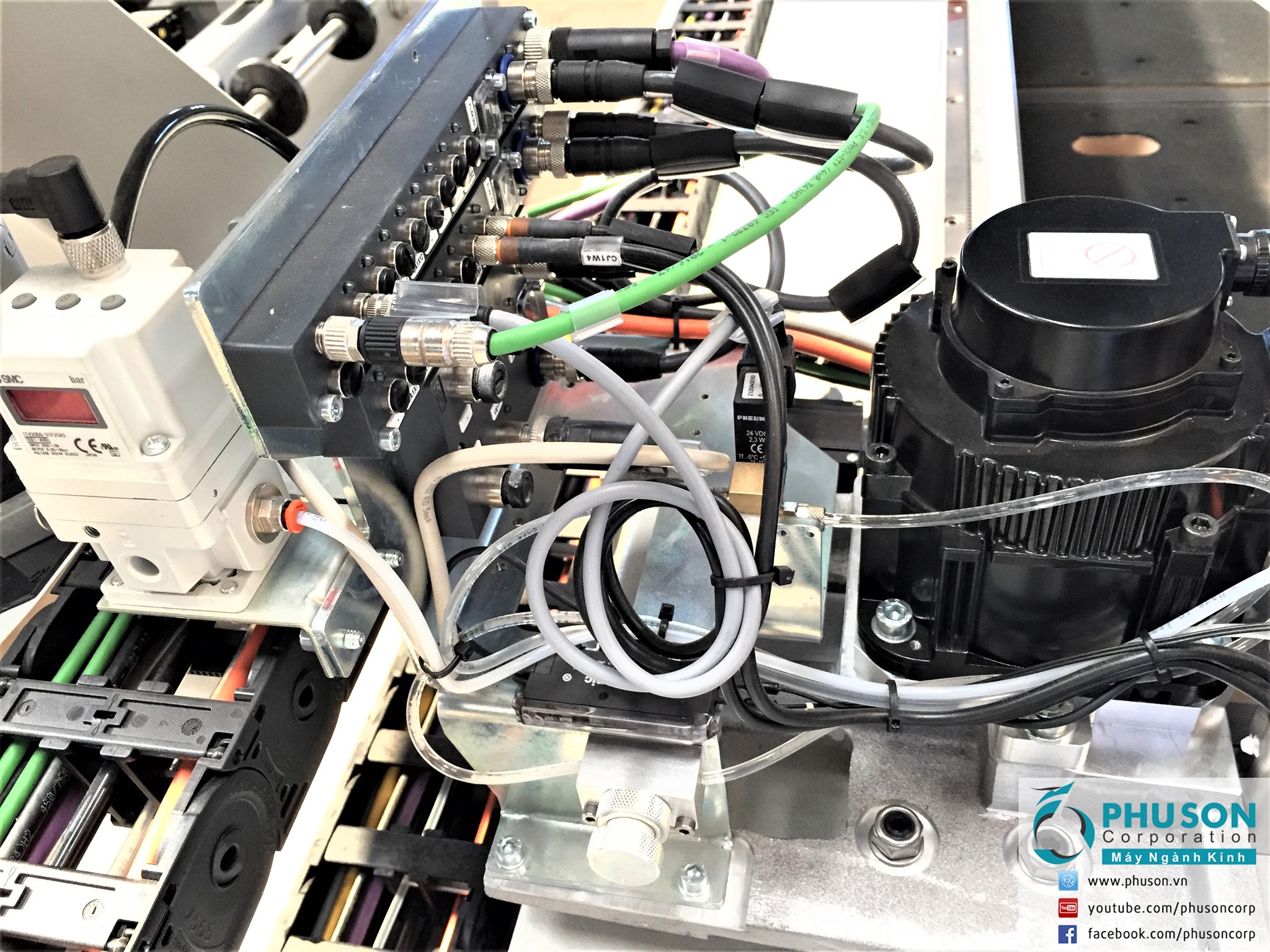

– Fully automatic control CNC + industrial computers

– Cutting size: 6100 x 3350mm – glass thickness 2-19mm, – Cutting speed: 200m / min. – Error: +/- 0.15mm / 2000mm.

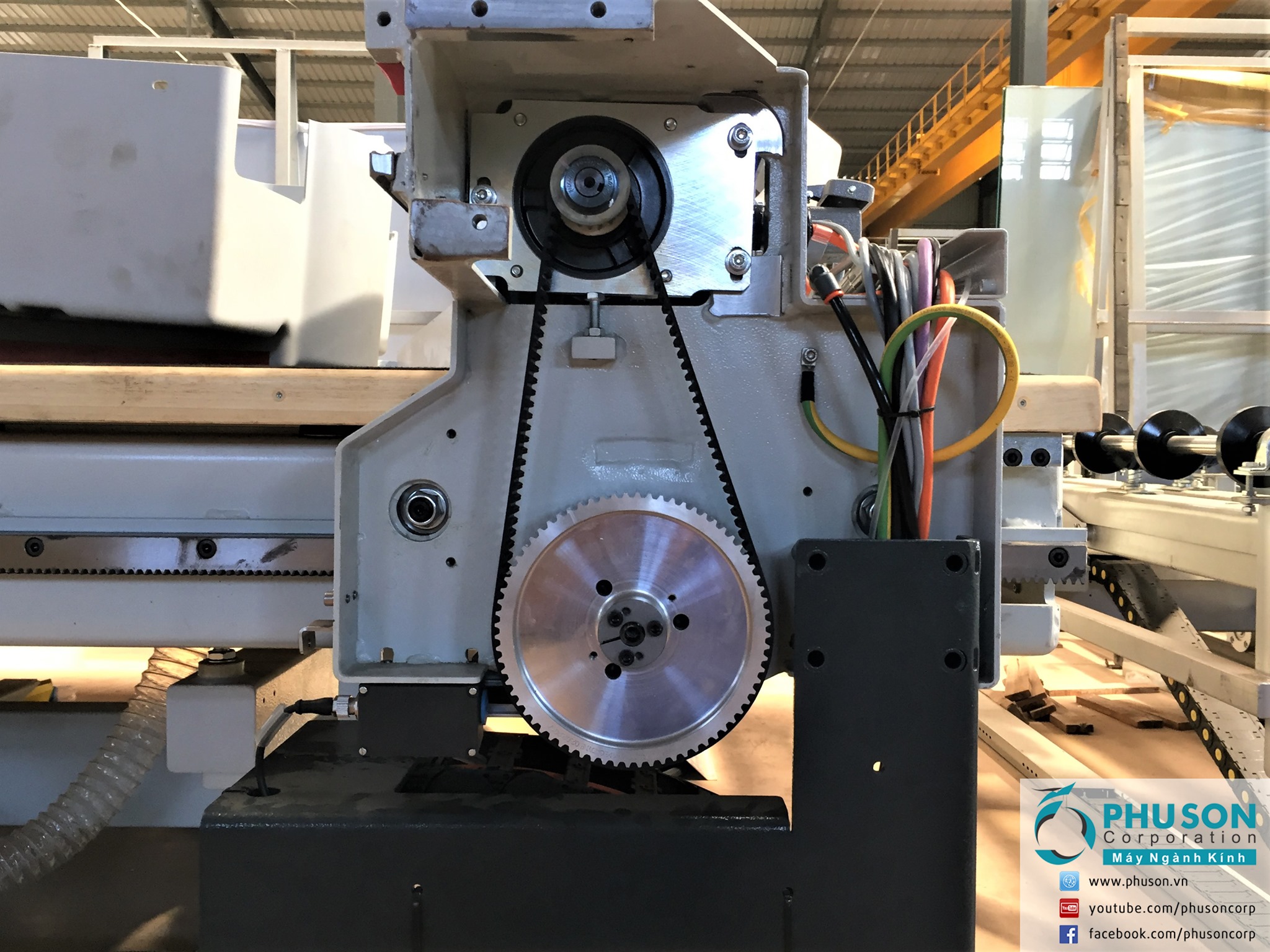

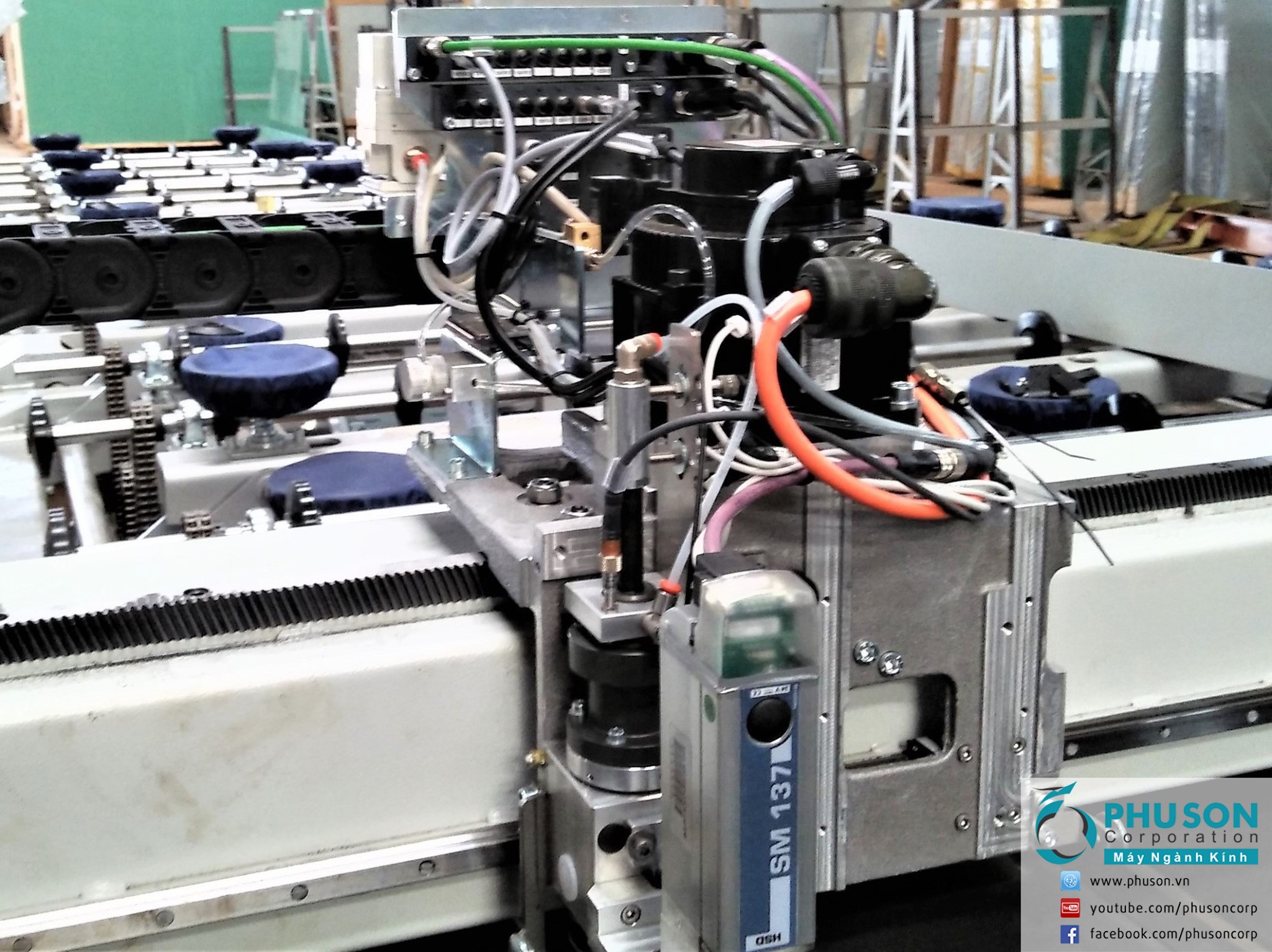

– The machine has 3 axis, independent C axis can rotate unlimited for shaped cutting (other normal machines will not have independent C-axis design so when do the shaped cutting, it will run slowly and cutting head will be dragged down to the glass, not automatically rotating according to the cutting request).

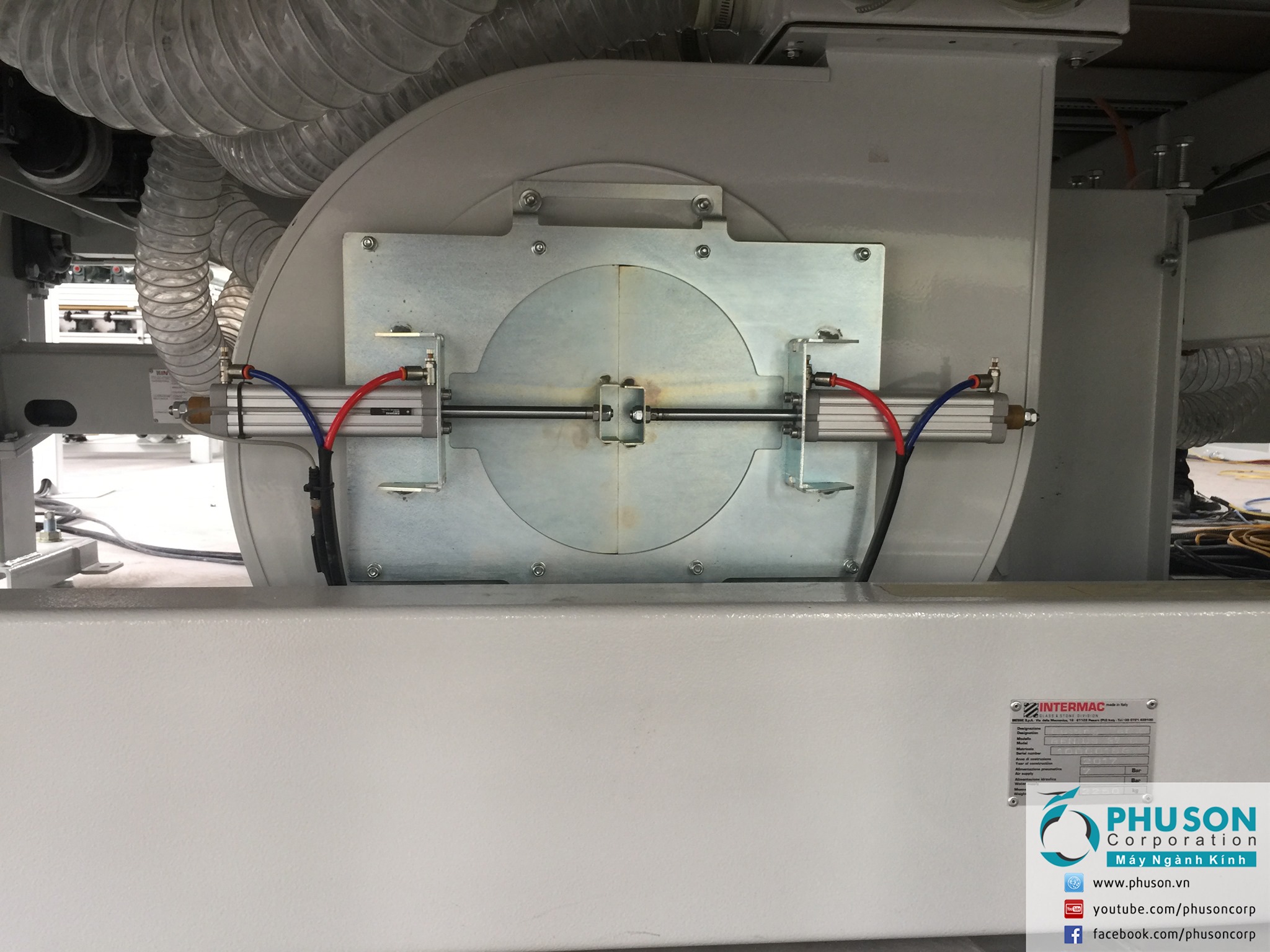

– There is a 6-point automatic tool change center that helps the machine automatically select the appropriate cutter for each thickness and straight or multi-shaped cutting immediately without human factors.

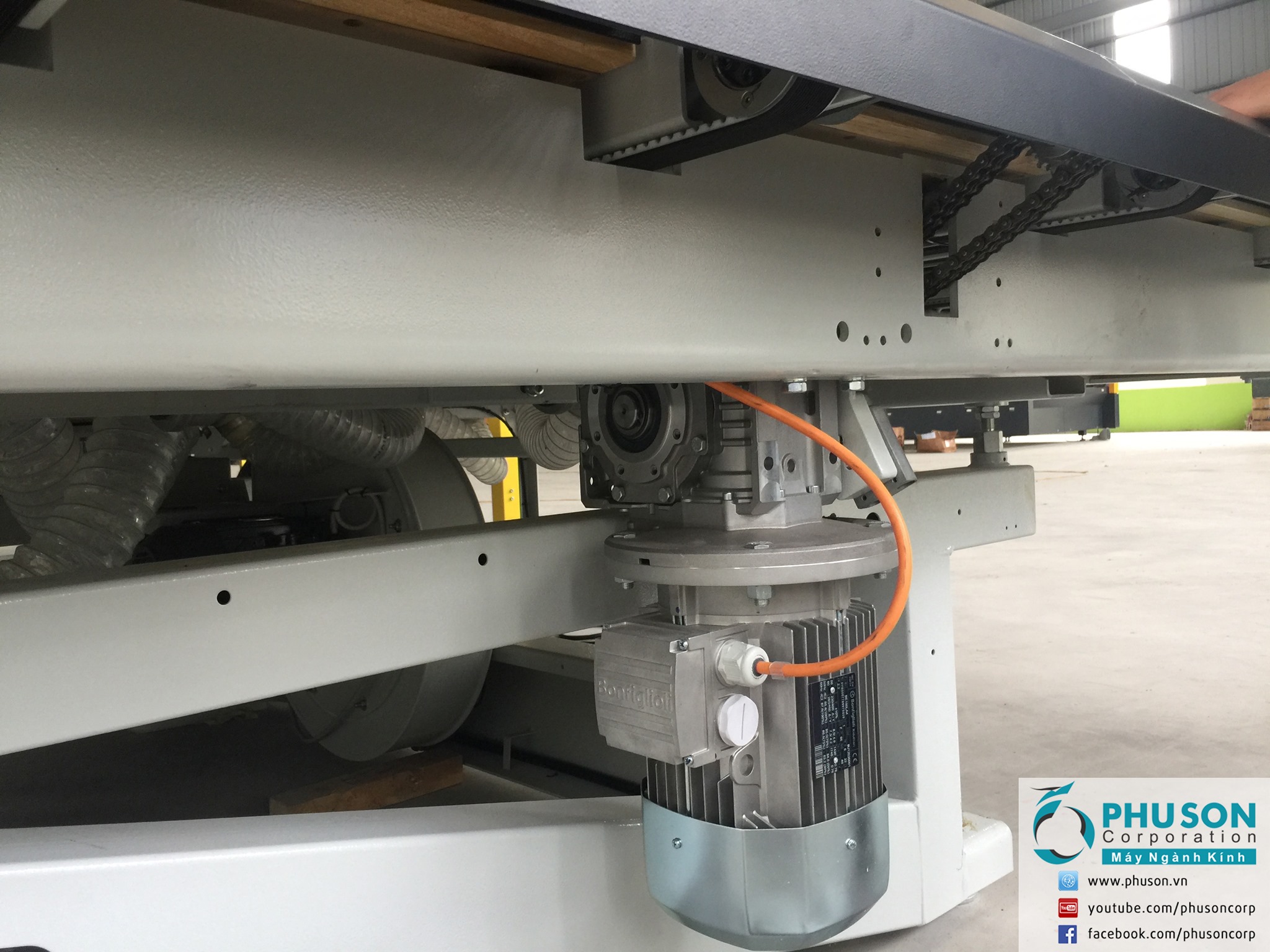

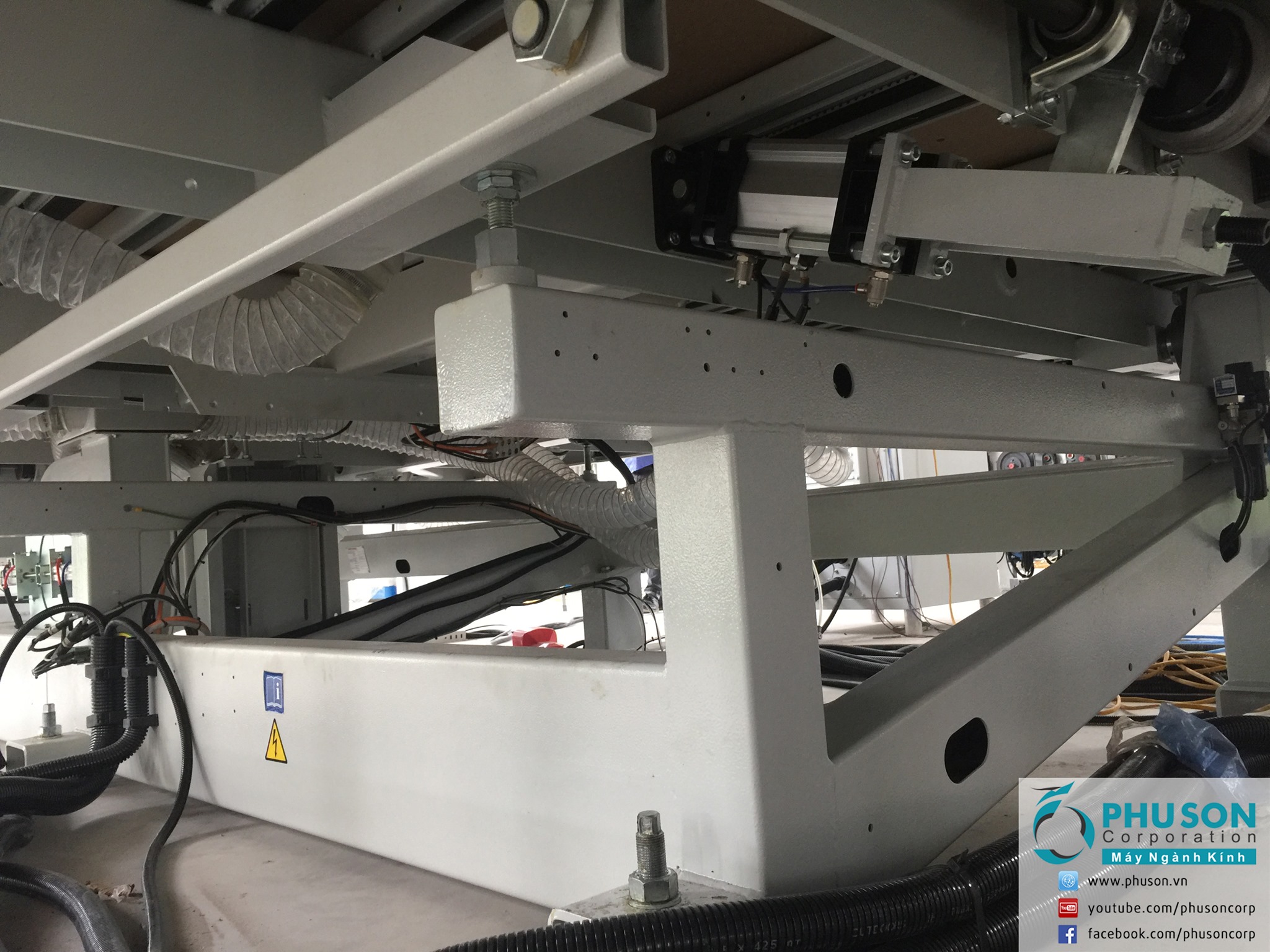

– The machine has a belt that automatically transfers the glass from the glass loading robot to glass breaking machine

– The machine can do the decal cutting on the glass that enable the processor to cut any sophisticated pattern, then peel off the negative part and sandblast or process with chemicals to form perfect glass art works..

– The machine has a copy function that helps the machine can copy any shape then reload that shape into the machine and cut to have final product 100% same as the original of customer’s order.

– The machine has zero positioning point and automatic positioning by lazer so that user can put the glass anywhere on the cutting table that still ensure the exact when cutting. These features also help machine can cut two-layer glass when cutting the section 1 then move and flip then cut section 4.

– The machine use Windows XP – Win 10, which has convenient and friendly interface with the operators and easy to control same as computer at the office. This can be repaired or replaced in Vietnam

– The machine includes Iedit optimization software package, label creation software (available with interfaces for logo and brand of glass processors, customer names or codes, order characteristics, barcodes or QR code, software to import data from Exel file or Text file format).

– The machine is made in Italy.