Welcome the new month with the preparation of the automatic delivery of CHAOYANG automatic U-shaped safety laminated glass production line with new generation of heat convection technology – increase of nearly 50% in capacity compared to normal lines about working speed for HUY HOANG GLASS factory right in August 2020.

CHAOYANG with the superiority in technology and quality of equipment lines, the quality of laminated glass products always meets the highest standards and meets the strictest technical requirements for high-rise building glass facades , including laminated glass with material is tempered glass, low.e glass and soft-coated solar-control glass.

The difference of CHAOYANG automatic laminated safety glass production line:

* The equipment line is really “quality” and really beautiful on even the smallest detail

* Modern overall design, high technology, intelligent control software * The washing machine is designed and manufactured by Bentteler technology – Italy with super quality on all details, fully automatic control through PLC and liquid crystal display, automatically stops fan when there is no glass into the drying chamber to save energy and cut off noise.

* The glass combining machine is designed super smart and “quality” on each component detail. Conveyor movement is designed with 3 sections which are independently controlled by 3 motors and 3 inverters to maximize production capacity. Intelligent positioning structure, vertical up and down 4 angles combined with robot movement by YASKAWA servo motor & driver, guided by slide rail and gear movement, is fully automatic controlled via PLC and liquid crystal display helps to create pairs of combining glasses with perfect 4-sided precision. The design with many sucker along with many fine-tuned sensor, springs and soft rubber nozzles helps to combine soft-coated low.e or brittle glass without easy broken the glass as normal equipments. Design automatic PVB film release machine by remote control 3 independent rolls.

*Air bubble pusher with 4 pressing rollers is designed to operate completely independently through 4 motors and 4 gearboxes with speed controlled by inverter. The rollers system’s speed is also adjusted by another independent inverter for absolute synchronization with the entire system of whole line. PLC control and liquid crystal display. Infrared heat generation with heat emission 1 preheating chamber and 3 main heat chambers. Heat convection technology by circulating fan system ensures the production of soft coated low.e laminated glass and tempered laminated glass with perfect quality, fast and even heating, low heating temperature on the glass surface… helps to speed up production and always ensure the quality standards of all kinds of goods.

*The high pressure chamber is designed to withstand 15MPA pressure with a large capacity forced convection fan to ensure that the batch is completed matching with the technical design for the chemical components of the PVB film, always in uniform, without air bubble, the film layer is always flexible, tough and durable in all weather conditions. All steps of production processes: from heating steps, pressure boosting steps, soaking steps, convection fan, air supply, air discharge, water pump is controlled by PLC through liquid crystal display automatically

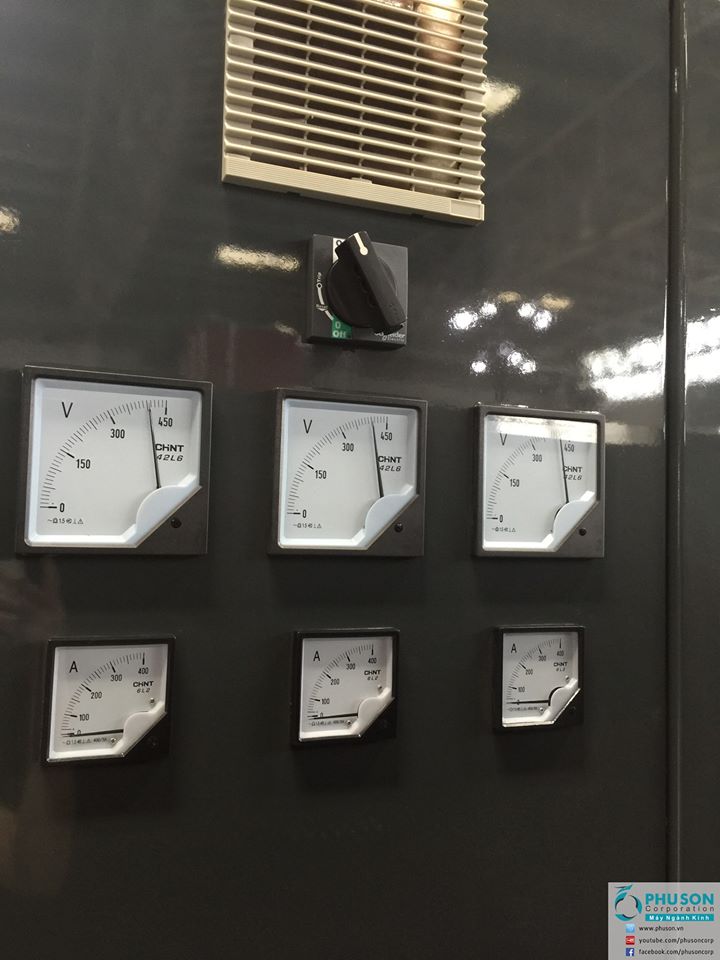

* Each stage all has a control system through PLC, liquid crystal display and separate electrical cabinets which are controlled completely independently and centrally control the entire line system.

* Glass is loaded continuously but never collides with each other and intelligent operation at all stages to optimize production speed.

* The electrical cabinet system is designed super professionally and meets European CE standards

* Super smooth operation, stable and durable

* 24/24 industrial scale production with very high capacity

* Finished products always meet 100% standard of Type I

With perfect capacity, experience and professional qualifications, engineers of PHU SON Corporation HN and HCM are always 100% proactive in installation, technology transfer and 24/24 after-sales without the need of any representation of expert engineers from the manufacturer at the factory throughout the years. This helps to ensure that installation progress and after-sales quality are performed instantly 24/7 in a professional and efficient manner under any circumstances. All bring maximum benefits and value to customers, manufacturers and suppliers themselves