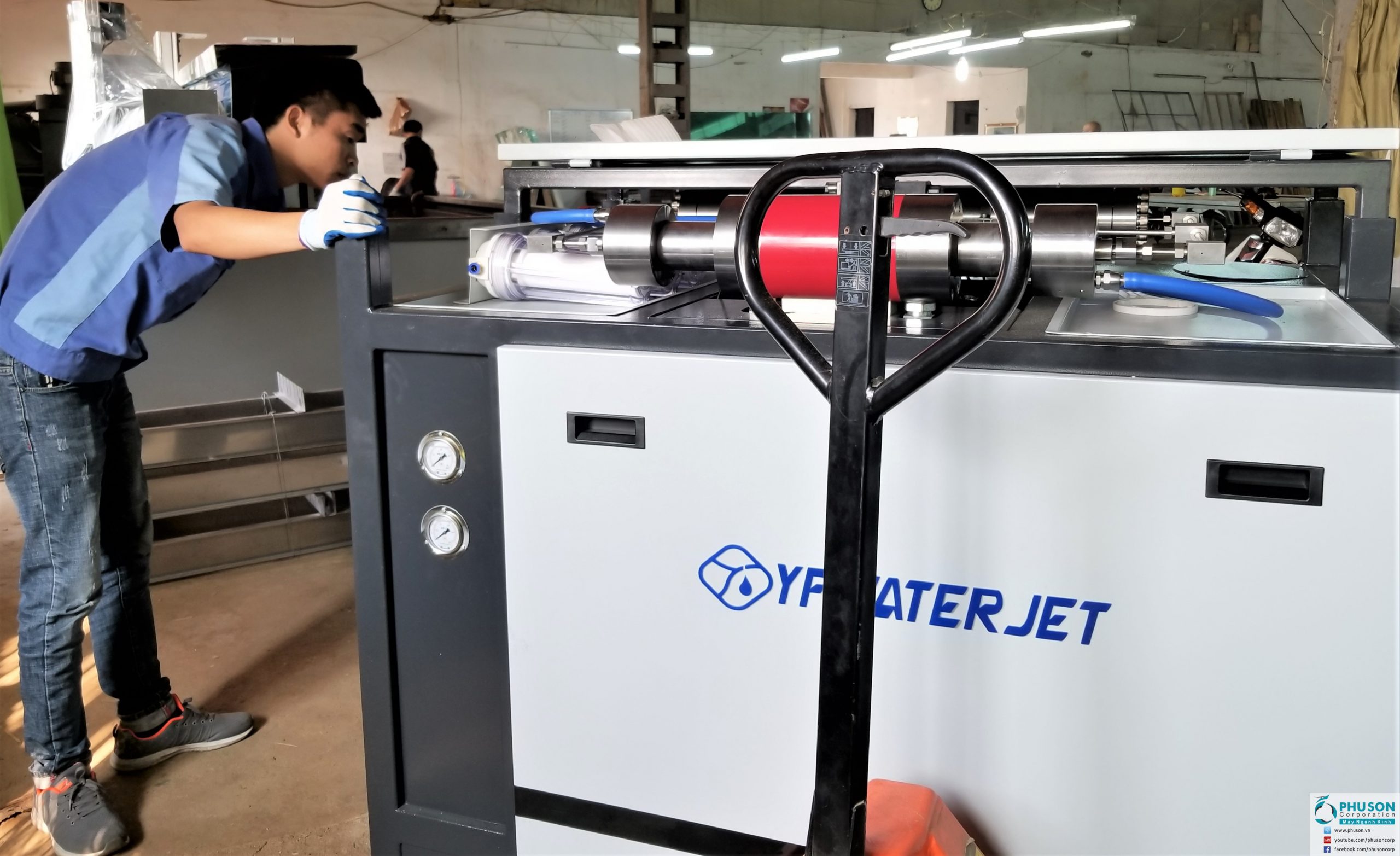

PHU SON Corporation HCM started to install an TENON automatic line of energy-saving insulating glass boxes, energy saving technology to automatically charge argon gas at the THIEN PHU GLASS factory.

With professional and technical competence, PHU SON Corporation can actively install, train, transfer technology and maintain warranty services to customers in a completely independent and independent manner. foreign experts, enabling the Company, its customers and manufacturers to pass through the Covid-19 pandemic in a powerful and effective manner.

The production line is equipped with standard features and specific orders for THIEN PHU GLASS:

* Producing box glass with glass material as Low.e glass and soft-coated Solar-control glass

* Automatic intake of argon gas on-line insulation

* Equipped with a thickness gauge, length, and many sensors vertically to help calculate the gas capacity to make the argon gas injection into the glass box most accurately

* Compressed chamber with many smart compartments to save argon gas when loading argon gas for each glass of different sized glass

* Producing all kinds of glass boxes: double boxes, 3 boxes, dimensional staggered boxes, boxes with big plates and small plates

* Producing oversized box glasses with double-press technology

* With intelligent control software and electronic components that help fast production speed, extremely beautiful products, continuous operation 24/24 is stable and durable

* The frame structure can be refined to help keep the flat surface of the two sides pressed after many years of pressing different sized glass panels, especially continuously producing evenly sized glass boxes for many easy days. loses the flatness of the entire face.

* Pressure tolerance: 0.3mm

* Press weight: 3 tons

* Breathing glass cavity by vacuum system

* Time to reach vacuum: 1 second

* It is equipped with the advanced ERP manufacturing management software